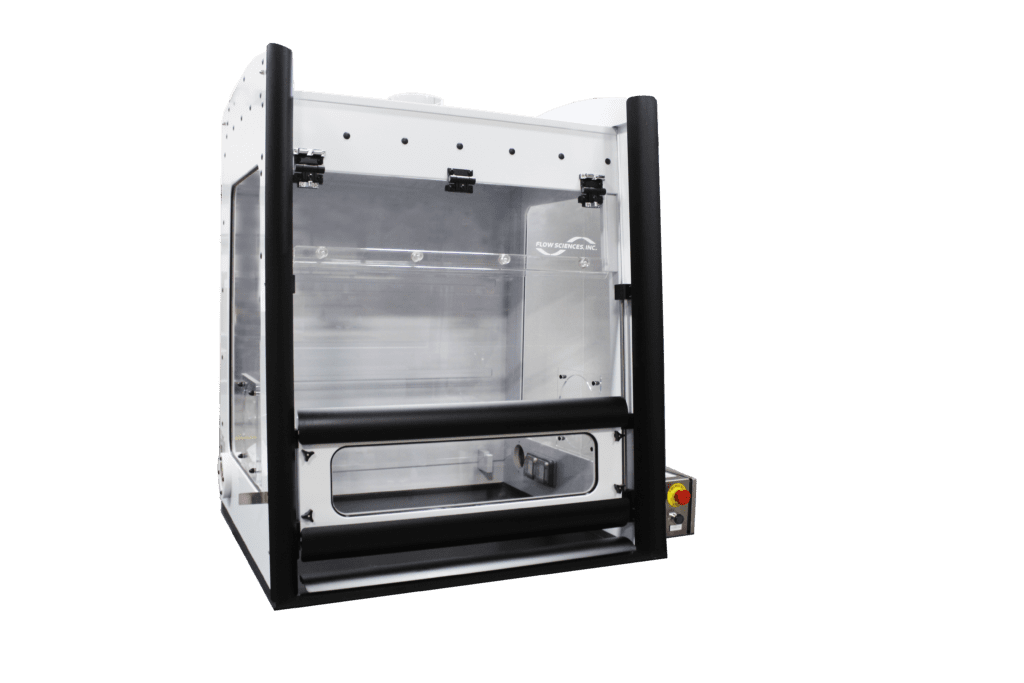

Agilent Bravo Automated Liquid Handler Enclosure designed to provide odor abatement and personnel protection from moving parts on the Agilent Automated Liquid Handler. Features removable sliding sash for loading and unloading of the Agilent Bravo. Features emergency stop (E – Stop) compatibility which stop machine from moving when the sash is raised*. The Agilent Bravo machine automatically resumes movement when the sash is lowered. Features polypropylene superstructure, acrylic viewing panels, and 3” diameter rubber membrane iris ports on each side to facilitate ingress/egress of electrical cables and cords.

Additional features include:

- Blanked port on each side (total of 2) for optional retrofitting of FS2070 Waste Chute and/or FS2079 Double Safe Waste Chute

- FS1650 face velocity alarm alerts the user when face velocity measurement is below the setpoint calibrated by the certifier

*Removable sliding sash features a limit switch which re-energizes the Agilent Bravo when the sliding sash is closed (machine movement immediately stopped when E – Stop function is activated)

Dimensions:

External Width: 35.75” [908mm]

External Depth: 34.00” [864mm]

Internal Height: 42.17” [976mm]