Our user-friendly configurator simplifies the process, ensuring your perfect fume hood is just a few clicks away.

Discover tailored solutions for Your unique needs. From powder to liquid and everything in between – Unlock the possibilities of our TaskMatch Database!

Empower your containment vision with Containment Process Builder (CPB) – Create, share, and see the perfect solution today!

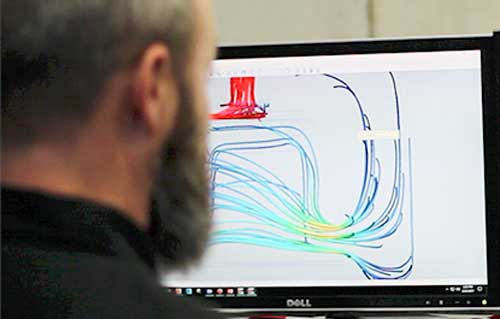

Flow Sciences’ team of containment experts bring decades of custom design expertise, with consistent compliments of creativity and adaptability, to global technological developments and processes.

Our sales, engineering, and project management staff begin by creating a unified understanding of your process and goals through the completion of our Custom Quote Request Form.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |