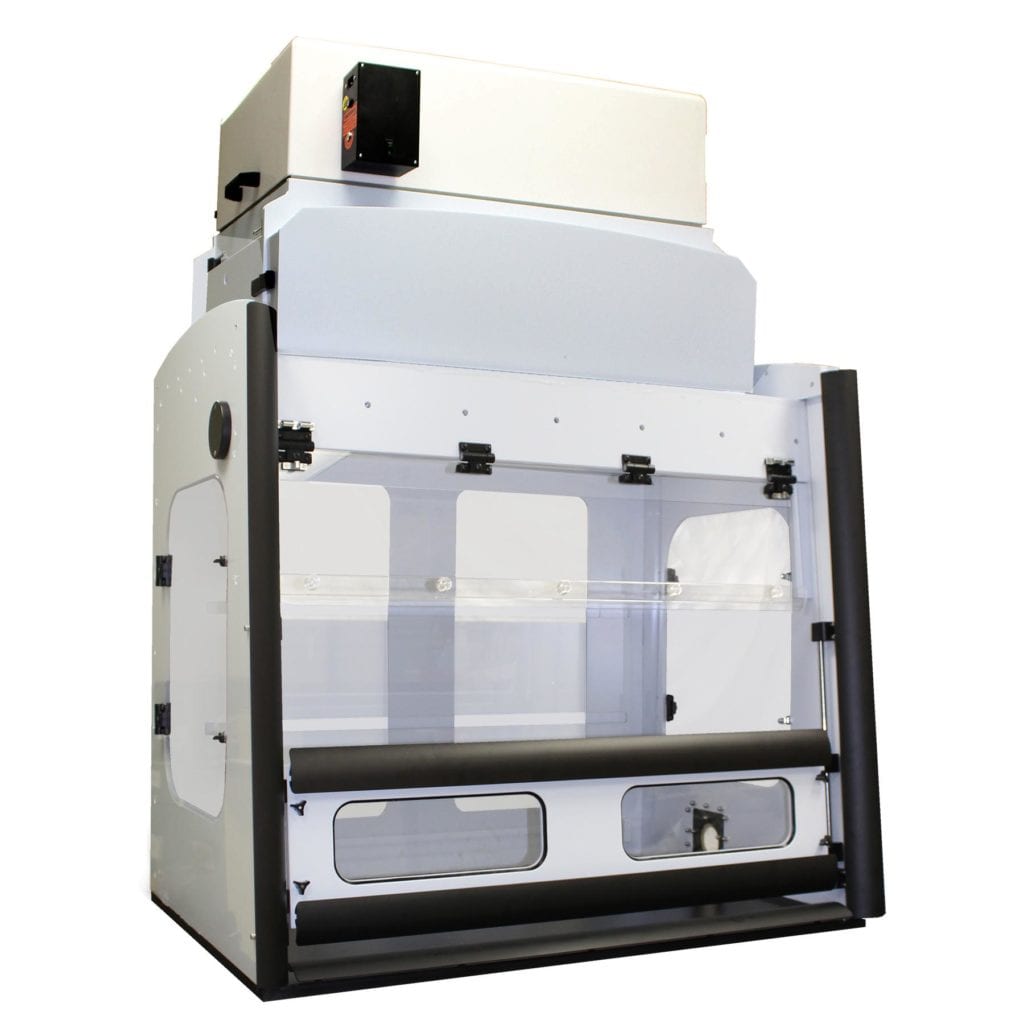

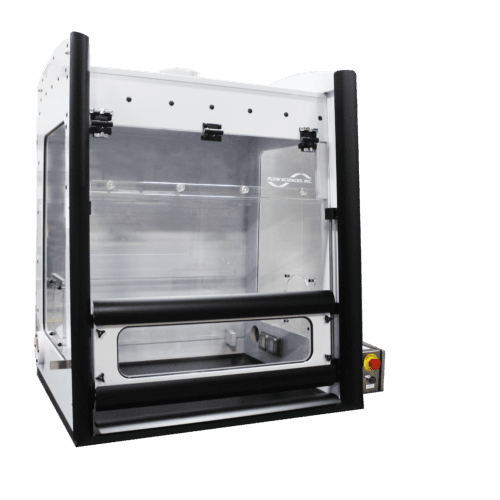

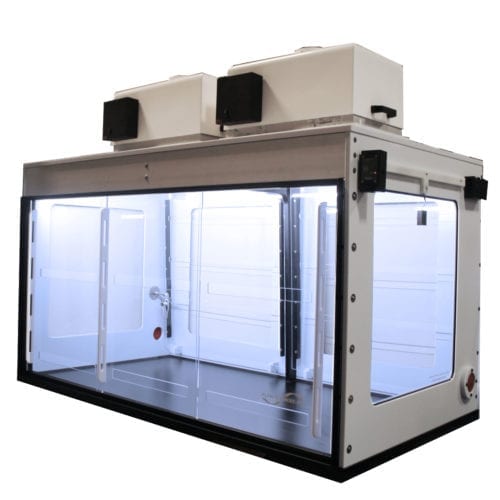

Xcelodose 600- Remote Dose Dispensing Enclosure designed for personnel protection during capsulation processes involving Xcelodose 600 Precision Powder Micro-Dosing System. Enclosure features polypropylene superstructure, top-mount fan with Dual-HEPA filtration. Removable sliding sash facilitates loading of equipment and unloading after decontamination. Access door featured on left and right side of unit allows user-manipulation when necessary.

Enclosure offers containment when operating under the following door configurations:

- Sliding Sash – High; where a 10” face opening exists below the sash

- Sliding Sash – Low; where a 10” face opening exists above the sash

Additional features include:

- Bag-In-Bag-Out (BIBO) system for safe replacement of primary filter

- Integrated airflow velocity alarm, which alerts the user when face velocity measurement is lower than the setpoint calibrated by the certifier.

Dimensions:

External Width: 49.39”

External Depth: 35.00”

Internal Height: 38.50”

FSI Category 4-5