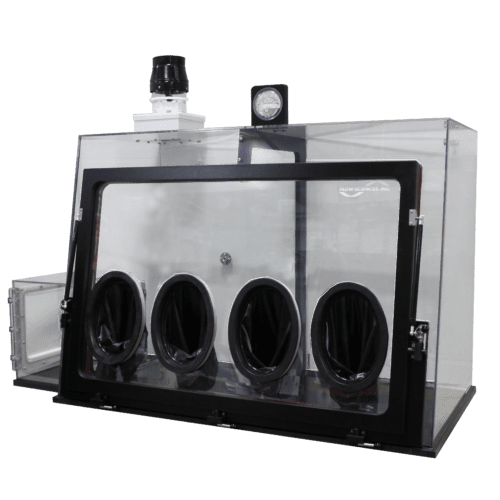

The Quadro Comil / High Shear Diosna Milling and Granulation Enclosure designed to provide personnel protection

down to a respiratory exposure concentration of 100 nanograms per cubic meter (ng/m3) during milling and granulation operations.

Enclosure features an acrylic superstructure colored Amber to provide containment of hazardous materials

away from the user when operated at specified face velocities. Design accommodates sufficient space for storage and usage of the following equipment:

- Quadro Comil 197 – [22.5”L x 12.5”W, 31.6”H]

- Diosna High Shear Mixer, Model P1/6 [30.5”W x 18.5”D x 20”H]

- Fluid Bed Mini/Midi Glatt [25.6”W x 27.6”D x 33”H]

Enclosure features include the following:

- 3-way light switch

- Minihelic differential pressure gauge

- LED Lighting Kit with White and Amber color settings

- Amber color settings intended to preserve product integrity

Dimensions:

External Width: 35.75”

External Depth: 26.56”

Internal Height: 24.28

FSI Category 10+