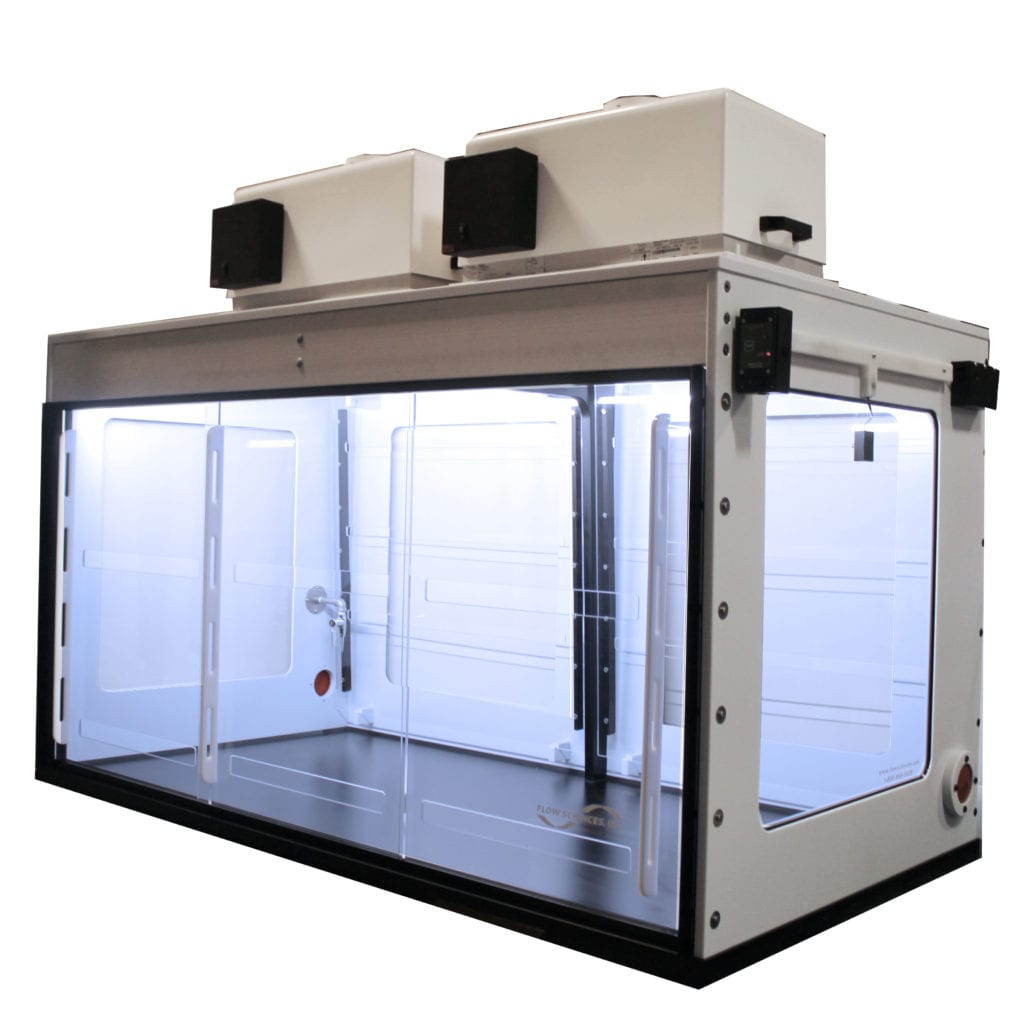

Wintech Blender and Mixer Enclosure designed to provide personnel protection down to a respiratory exposure concentration of least 1 milligram per cubic meter air (1 mg/m3) during blending and mixing operations. Accommodates space for a Wintech blender, a hand sieve, Umang High Shear Granulator, and analytical balance. Enclosure base is coated in black phenolic rein for preservation of accuracy and precision of mass measurements; base is dished along perimeter to contain spills. (3x) removable sliding doors allow for easy loading and unloading of equipment.

Enclosure features include:

- 3” rubber iris port on left and right side of enclosure to facilitate entry/egress of equipment cables and cords

- LED Lighting and acrylic viewing panels for optimal viewing of the workspace

Dimensions:

External Width: 71.25”

External Depth: 39.66”

Internal Height: 36.69”

FS1 Category 6-7