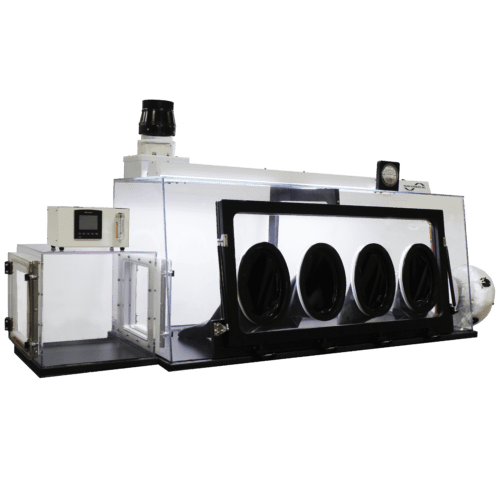

Textile and Furniture Manufacturing Nuisance Odor Abatement Enclosure designed to provide personnel protection during processes involving applications / operations, which produce nuisance odors. Observable effects of nuisance odors are proven nonexistent in the [interior] concentration range of 1000-5000 micrograms contaminant per cubic meter air(*).

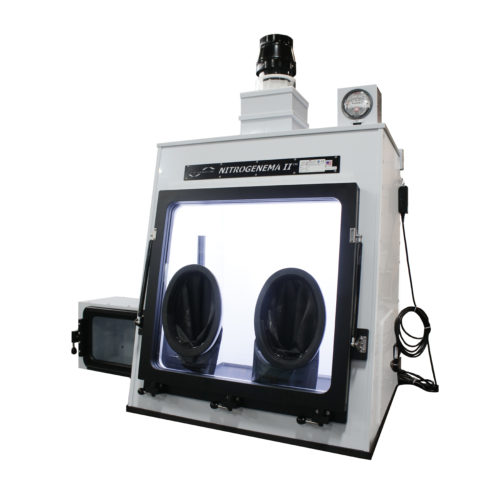

Removable sliding doors offers six (6) door – opening permutations equipment and efficient loading / unloading of equipment and product. Control box on upper – right features light switch, which allows the user to activate an LED light for better viewing of the workspace in necessary conditions.

(*) proven by internal performance validation testing (aka. FAT)

Additional features include:

- 3” rubber membrane iris ports allow for ingress / egress of equipment cables and cords

- FS1650 alarm alerts the user when face velocity is below the setpoint calibrated by the certifier

Dimensions:

External Width: 58.00” [1422mm]

External Depth: 32.00 [813mm]

Internal Height: 41.69” [1059mm]