Process:

Customer required a cart-to-dock enclosure to house a Malvern Mastersizer 3000 with Aero S and Hydro MV accessories while providing personnel protection. The PC was to be stored below the cart on a shelf and the enclosure customized to have an articulating monitor mount field-installed upon delivery. The Mastersizer 3000 uses the technique of laser diffraction to measure the size of particles. It does this by measuring the intensity of light scattered as a laser beam passes through a dispersed particulate sample. This data is then analyzed to calculate the size of the particles that created the scattering pattern. The Mastersizer 3000 software controls the system during the measurement process and analyzes the scattering data to calculate a particle size distribution. It also provides both instant feedback during method development and expert advice on the quality of the results.

Containment:

With dry powder dispersion there is always the possibility of particle damage, because of the high velocity at which the particles pass through the disperser system. The Aero S minimizes this issue by avoiding impaction surfaces. The Hydro MV is designed for medium volume wet dispersion and is suitable for a very broad range of sample types. Automated dispersant delivery of both organic and inorganic dispersants allows optimization of the dispersion process and accelerates analysis. These devices—the Mastersizer, the Aero S, and the Hydro MV—require Dual HEPA filtration in order to minimize lab contamination.

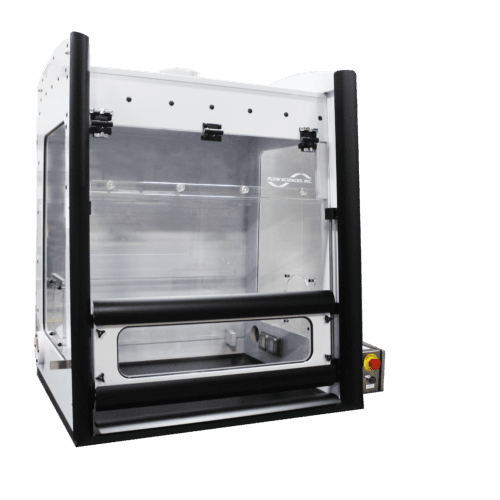

The enclosure cart with its black phenolic top would seat the units and allow for removal when devices required maintenance, and a vertically sliding sash with the ability to be raised above safe operating zone for equipment loading/unloading. The cart was constructed of white steel a locking mechanism and guide rails for it to inset into the table upon which the enclosure sat. Penetrations in the form of iris ports were added to the polypropylene frame to allow for entry/egress of critical cabling to power the various devices. Front bifold doors in the cart allowed for the PC base to be stored. In order to maintain light across the entire work surface, an LED lighting chase was designed and integrated into the enclosure ceiling.