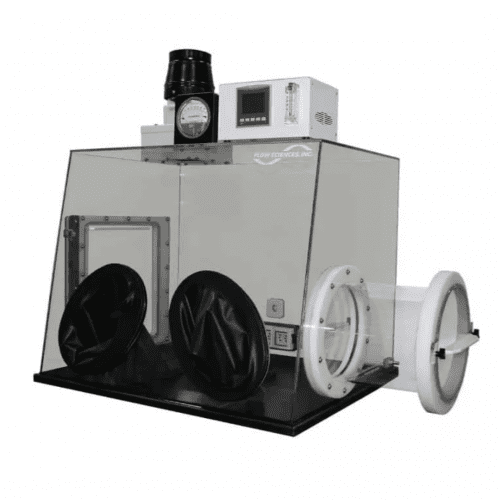

Hamilton Starlet and Liconic Assay Incubation Enclosure designed to provide personnel protection from liquid substances when performing assay chemistry operations involving the Hamilton ID Starlet with dimensions (L x W x H) 31.3” x 39.7” x 44.3” [795mm x 1008.38mm x 44.3mm] and a Liconic STX-Series (or similar) incubator with approximate dimensions (L x W x H) 51.18” x 51.18” x 74.80” [1.3m x 1.3m x 1.9m]. Enclosure features aluminum frame superstructure and black phenolic resin-coated base, dished to contain spills.

To facilitate “load and go” functionality, enclosure features the following passageways for loading and unloading of automated and / or robotic equipment.

- (3x) sliding doors on upper front portion of unit

- (3x) sliding doors on lower portion

- Removable cross members (horizontally bisects upper and lower portions across whole perimeter of unit)

Enclosure was designed to function as secondary containment under biological laboratory work area conditions. (2x) 6” diameter exhaust ports on top of unit allow for connection to house exhaust. Flow Sciences, Inc. offers an array of vent kits at an additional cost.

For optimal height of workspace, Flow Sciences, Inc. recommends that you consider a table compatible with the dimensions indicated below. For information regarding Flow Sciences, Inc. tables and accessories, please click here.

Additional features include:

- On right side: Door handles for ergonomic removal viewing panels

- On front: door handles on right-most column and center column of sliding doors

Containment is provided when one sliding door is opened on either the upper row of [front] sliding doors of lower row of [front] sliding doors.

Dimensions:

External Width: 87.00”

External Depth: 60.00”

Internal Height: 84.47”

FSI Category 9-10