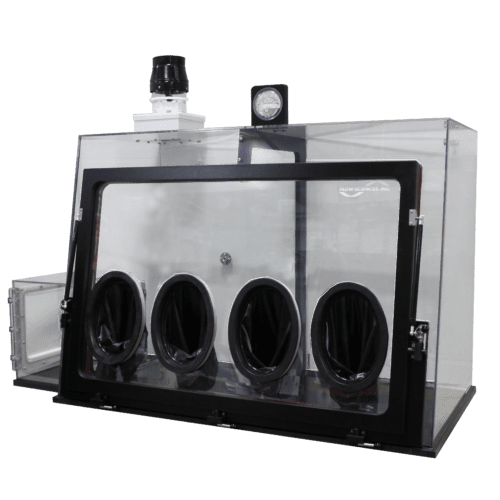

Vaccine API Weighing and Processing Glovebox Workstation designed to provide personnel and product protection during the weighing and manipulation (processing) of Active Pharmaceutical Ingredients; provides attenuation of breathing zone exposure down to concentration ranges corresponding with OEB 4 (Occupational Exposure Band 4)(*).

Front access door with (3x) oval glove ports allows the user to access the workstation interior using gloves, thereby being protected from respiratory and dermal exposure when conforming to good laboratory practices; cuffs and sleeve accessories available for purchase upon request. Pass-thru chamber on left allows the user to load containerized product into the workstation while retaining containment(^); pass-thru dimensions are 11.875” x 10” x 12” (Width x Depth, Height) and pass-thru door dimensions are 8” x 9” (lateral width x height).

Glovebox Workstation provides product protection via lateral airflow across the workspace, which is facilitated by the combination of a 24” x 14” inlet HEPA filter on the right side and a Top – Mount Dual – HEPA fan / filter housing. Lateral airflow dynamics protect product from cross-contamination and loss incurred by direct contact with air channels.

Control box on left side of workstation features integrated airflow alarm (FS1650), tower light (aka. stack light) with Green / Red light indicators and audible containment breach alarm, and ON / OFF switch for fan.

Note: the 8” continuous liner, depicted in the photo above, is available for purchase upon request

(*) Per the United States Center for Disease Control and Prevention (CDC), the target range of exposure concentration is less than 0.01 milligrams dust [and / or powder] per meter cubed air (<0.01 mg/m3) – OEB 4 is typically assigned to substances deemed very toxic on single exposure, substances associated with adverse teratogenic / reproductive effects, sensitizers

(^) containment is provided with all doors closed, including door between pass-thru chamber and workstation interior

Additional features include:

- Minihelic gauge on Dual – HEPA fan / filter housing displays real-time measurement of differential pressure between the surrounding [ambient] environment and the inlet side of the primary HEPA filter

- Minihelic gauge on top-right side of workstation displays real-time measurement of differential pressure between the surrounding environment and the workstation interior

- Base is coated with black phenolic resin, which offers stability of mass measurements

- Base is dished to contain accidental spills

- Roxtec cable pass-thru allows for ingress / egress of equipment cables and cords while maintaining containment – It is recommended that good laboratory practices pertaining to decontamination be followed.

Dimensions:

External Width: 60.00” [1524mm] – workspace only, 72.38” [1838.45mm] – workstation and pass-thru

External Depth: 33.90” [861mm]

Internal Height: 24.98” [635mm]