DESCRIPTION

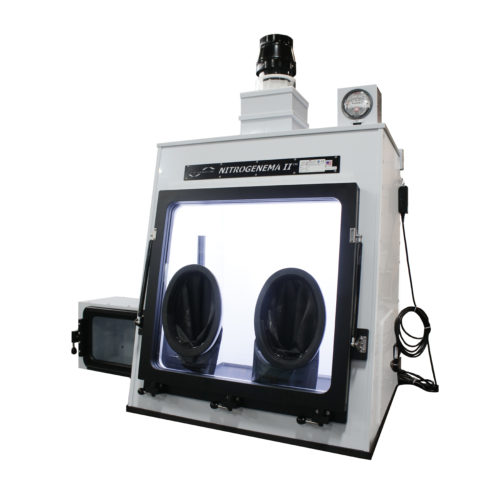

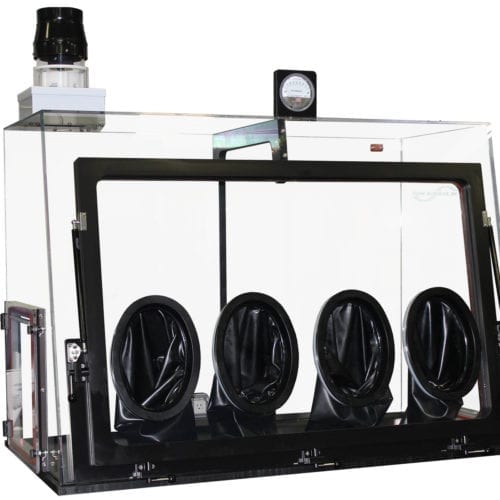

Oncoloy Workstation with EziDock CSV6 HPAPI Transfer designed to provide personnel and product protection while working with powder substances. Enclosure features include polypropylene superstructure, black phenolic base, Inlet 18” x 36” HEPA Filter, front door with gas shocks, 4x 10” oval glove ports, glass viewing panels, left-side pass-through, LED Control Box with Integrated Velocity Alarm, top mount fan with BIBO HEPA filtration, magnahelic pressure gauge, and a stainless steel table with leveling feet. LED lighting and glass viewing panels maximize lighting across the workspace.

Enclosure Dimensions:

72” Exterior Width

34” Exterior Depth

37” Interior Height

The Oncology Workstation with EziDock CSV6 HPAPI Transfer was designed to provide personnel and product protection while working with powder substances. It was determined due to the high OEL that a glovebox workstation would best suit the application, and an Ezi-Dock high containment transfer system was integrated into the black phenolic base. The Ezi-Dock transfer system was used due to its capacity to handle hazardous chemical and pharmaceutical products. A containment level of 50 ng/m3 was required.

Powders contained in drums would have to enter the workstation via a passthrough, which had to be large enough to handle multiple dimensions. The door opening in the front of the passthrough, as well as the sliding door which allows entrance into the glovebox work area, had to be congruent. A list of all container sizes was procured and the passthrough was designed to fit over 70% of the proposed containers.

Due to strong cleaning materials that would be used, the viewing panels of the workstation were made of glass as opposed to acrylic, as the potency of the cleansers would craze the lucite material. The single glass panel in the polypropylene frame that contains the glove ports would be affixed to the enclosure via gas shocks. Efforts were taken by the design team to limit the weight of the door in order to ensure longevity and proper function of the hinges and shocks, as well as make the cleaning operation simple enough for one operator. The design team’s precautionary solution was to fabricate a door that was 70 pounds—15 pounds less than the original concept. Other design considerations included increasing the door width to decrease interference with the grooved seals around the edges. The pull of the fan in operation also yielded an issue with the top plenum, which was too light to stay seated. Rabbit edges were designed for a flush fit, and the thickness of the material was increased.

The customer requested that the door angle reach 140-150 degrees when open, knowing that containment would only be provided if the unit was completely closed. The 140-150-degree request of the door was to allow for entry/egress of the powder weighing equipment and containers, in order to facilitate an easier, and more thorough cleaning process. An electrical duplex was added to the back wall with two single outlets and a Roxtec connection besides the outlet on both sides.

Overall performance during acceptance tests indicated that the enclosure met required specifications. The enclosure passed all requirements for ASHRAE and AIHA/ANSI standards and recommended practices and met the CPT of 50 ng/m3. The results indicate that with good laboratory practices, this enclosure is highly effective at providing containment for compounds with Occupational Exposure Limits (OEL)s < 100 ng/m3.