ABSTRACT:

Frequently, customers have used fume hood exhaust to ventilate hood base cabinets. The author finds both the need for this practice and the designs for them are frequently not well thought-out.

Alternate rationales and approaches to this ventilation method are reviewed with clear-cut recommendations.

The Historical Rationale for Cabinet Ventilation:

An acid cabinet contains jugs of concentrated acid which can give off fumes if improperly stored with loose caps or drying spills on the jug exterior. Solvent cabinets store solvents which could contribute to a lab fire if internal solvent fumes caught fire. For years, lab designers have assumed these issues could be addressed by gently pulling air through these cabinets and into the fume hood. No fumes; no danger. It’s as simple as that!

The Realities of Specified cabinet ventilation:

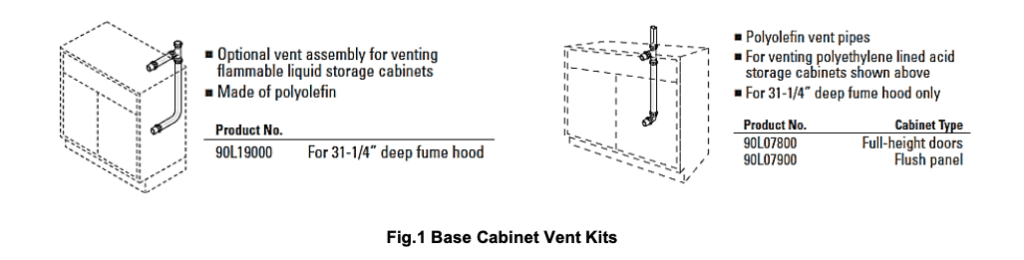

Reflecting this concern, cabinet vents have been called out in construction specifications for laboratory chemical fume hoods with base cabinets. Here is an example of a construction specification for a cabinet vent for flammable (solvent storage) cabinets:

“Chemical hoods shall have ventilated base cabinets that comply with NFPA 30, with a built-in partition for separation of incompatible chemicals. Except in ADA hoods, the cabinet shall be able to hold four liter sized bottles on both the top and bottom shelves. 1”

However, NFPA 30 says the following about vented fume hood cabinets containing flammables 2:

9.5.4* Storage cabinets shall not be required by this code to be ventilated for fire protection purposes.

9.5.4.1 If a storage cabinet is not ventilated, the vent openings shall be sealed with the bungs supplied with the cabinet or with bungs specified by the cabinet manufacturer.

9.5.4.2* If a storage cabinet is ventilated for any reason, the vent openings shall be ducted directly to a safe location outdoors or to a treatment device designed to control volatile organic compounds (VOCs) and ignitable vapors in such a manner that will not compromise the specified performance of the cabinet and in a manner that is acceptable to the authority having jurisdiction.

The need for venting corrosive (acid) storage cabinets is also defined by some institutions. The University of Wisconsin sets forth the following: 3

Optional chemical storage cabinets: For those fume hoods provided with VENTED under counter chemical storage cabinets to reduce odor, each cabinet shall be connected to a 1.5-inch diameter vent tube which penetrates and is sealed to the fume hood countertop. The tube shall also be sealed to the chemical storage cabinet in the rear side wall and terminate behind the fume hood baffle.5

One may note the lack of detail in this description. Critical data such as cabinet exhaust rate is completely ignored. 4

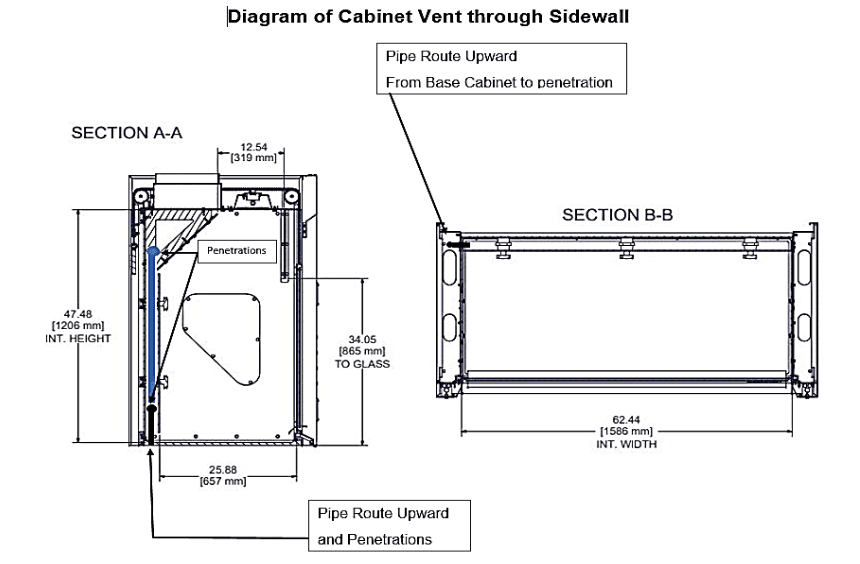

With the lack of such specificity, lab equipment providers have been left with a default definition of a vent tube running from the cabinet through the work top into hood baffle area. An illustration of the approach is shown below 5:

Two comments need to be made here regarding these illustrated approaches:

1 – Neither acid cabinets nor solvent storage cabinets use this approach consistently. In the field, such cabinets frequently have no ventilation system whatsoever!

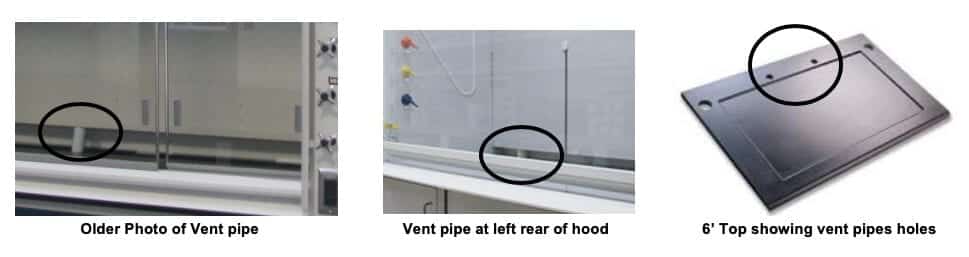

The author attempted to find some photographic evidence online that vents from cabinets into fume hoods were still being used; I found limited photographic examples. Below, note examples I did find:

Clearly, this default approach is not universally used.

2 – Justification for such a venting procedure is questionable.

Let’s take each cabinet type separately and examine the problems with venting it using a tube into the fume hood rear:

- Acid cabinet venting:

- How much air will go through such a cabinet using the vent system with specifications, as described previously?

The cross section of this pipe is (pi)r2=0.752 X 3.14 = 1.76 sq. in = 0.0122 sq. ft.

At a hood face velocity of 100 fpm, CFM = V*A = 100 * 0.0122 = 1.12 CFM

A 36” base cabinet has an internal area of 22” X 34” X 36” =26,928 Sq. inches, or 15.6 cubic feet. This leads us to have a cabinet with 1.12/15.6 = 0.07 air changes per minute (ACM); or 4.3 Air Changes per hour. When the door of the cabinet is opened, it would have a face velocity of 1.12 CFM/8.5 sq. feet = 0.13 FPM. Hardly capable of containing any fumes!

- Is there any way to stop the escape of these fumes without the vent? We have just shown this type of vent is barely effective with venting fumes from cabinet acid spills and incapable of preventing fumes from escaping if the cabinet door is opened! There is little rationale for using such a vent system which attempts to piggyback cabinet ventilation of the fume hood exhaust.

More robust ventilation may be achieved by venting such a cabinet through the baffle area at the hood top. In this region of the baffle, there is a larger negative static pressure and therefore more “draw” on the base cabinet vent port. A schematic of such a system is shown below:

One can also use shelf liners inside the cabinet made from inexpensive cement board which is primarily limestone Ca(OH)2, a base. Such a sacrificial panel can neutralize (ionize) small drips of acid, and reduce fumes. All Flow Sciences acid cabinets come with this feature as standard.

Additionally, it is highly recommended that standard operating procedures (SOP’s) include steps mandating the cleaning of liquid acid off of glass containers and firmly closing each cap (ensuring a sufficiently tight seal) before returning the containers to the acid cabinet.

- Solvent Cabinet Venting:

- The “flow” through the cabinet with a 1.5” vent does not facilitate a sufficient volumetric flow rate to remove spilled solvent vapors from the cabinet. See [1. a) 1)]

- Solvent cabinet doors, unlike acid cabinet doors, have no vent holes. As noted above, the double-walled cabinet is supposed to keep heat out to prevent cabinets from allowing their contents to burn in a general lab fire. As a practical matter, these cabinets are virtually air-tight when closed. This means that the 1 CFM throughput calculated with the louvered acid cabinet would be even lower with the non-louvered solvent cabinet.

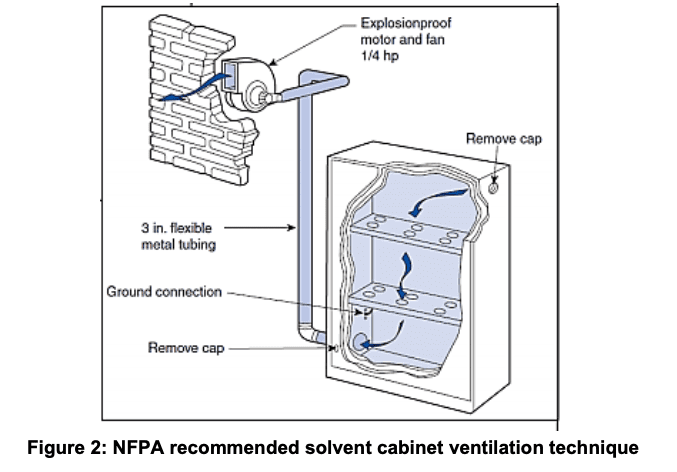

In the defense of NFPA, the association included in NFPA 30 the required way to vent a solvent cabinet, and it is not with a vent kit through the work top. See below 8:

Figure 2: NFPA recommended solvent cabinet ventilation technique

While this method assures more robust ventilation, it increases airflow through the cabinet, which will increase the amount of heated air running through the cabinet in a combustion area.

Keep in mind, a solvent cabinet is designed to keep heat out during a lab fire.6 It is UL 1275 tested with a heated oven that elevates external cabinet temperature to ~1300OF over 10 minutes while cabinet internals must stay under 350oF. This test is purposely run with NO ventilation through sealed bung holes! 7

Imagine repeating this test with an actively ventilated solvent cabinet. Now air being passed through the cabinet from a burning environment at a severely elevated temperature would elevate the temperature of the cabinet interior. In this case, higher levels of cabinet exhaust will draw more fire-heated air into the solvent cabinet. This is definitely at cross-purposes with the cabinet’s design intent!

This entire analysis is also summarized in many catalogs, including Grainger, who point out:

Don’t Vent Unless You Have To

“While cabinet manufacturers may provide the bungs for ventilation purposes, venting flammable liquid storage cabinets is NOT required or even recommended by any federal regulatory agency. Cabinet manufacturers include venting bungs for users who may be required to vent by state or local codes, individual company policies, insurance carrier policies or any other authority having jurisdiction (AHJ).”

So, is there any way to stop the escape of solvent fumes without the vent? There really is not, particularly when NFPA does not require venting and mandates elective vents use an independent fan as shown in figure 2. Again, SOP’s in various facilities may recommend different things. But always use approved solvent containers. and clean up spills to prevent fire-friendly conditions in the lab!

Summary:

- Do not ever use a through-the-top vent system and expect the safety of an acid cabinet to be improved. If local standards require this venting procedure, do your best to design countermeasures to neutralize the added risk.

Always use sacrificial shelf liners that neutralize acid. Enforce SOP’s that require closing acid bottles tightly. Consider one of the more robust method of ventilating the cabinet discussed in this paper.

- Do not ever use a through-the-top vent system and expect the safety of a solvent cabinet to be improved. Venting in this manner is an arguably futile containment strategy based on the low airflow through such a vent.

If local standards require a venting procedure, follow NFPA recommendations as set forth in NFPA 30, and do your best to design countermeasures to neutralize the added risk.

It is likely fire authorities will prefer the separate remote fan method outlined above that is advocated by NFPA 30. In addition, enforce SOP’s that require special solvent canisters with spring closures, and clean up spills inside the cabinet immediately!

3. One final note regarding the fume hoods in all of the above examples. A separate question exists about whether such fume hoods should be left running or turned off during a fire. You can imagine this question is even more complex and significant than base cabinet ventilation.We will discuss this issue in an upcoming White Paper.

Footnotes:

- Laboratory safety Design Guidelines, University of Medicine and Dentistry of New Jersey, 1/3/2007

- NFPA 30, 2012 Edition, p 30-28

- University of Wisconsin Department of Environment6al Health and Safety, Acid Cabinet Specification, (Un Dated), https://ehrs.upenn.edu/health-safety/lab-safety/lab-design-equipment/acid-cabinet-specification

- SEFA, as of 2017, does not set forth anything more than a discussion about where cabinet may be justified, without ever stating the mechanism for how it is to be achieved.

- Thermo Scientific Hamilton Air Flow Products, 2010, p.105, 106

- The 10-minute time limit limit iwas decided as time enough in a fire to evacuate personnel and to allow sprinklers to activate. file:///C:/Users/drbob.FSIDOMAIN/Desktop/TT-Safety-Cabinet-Performance.pdf

- The time temperature curve as defined by ASTM E119, UL 263 and NFPA 251 are virtually all the same: The curve starts at 68°F (20°C) at 0 minutes, continues to 1000°F (537°C) at 5 minutes, and for safety cabinets finishes at 1300°F(704°C) at 10 minutes as measured on the outside above the flame. The actual flame touching the cabinet can measure ≈1600°F (871°C)., file:///C:/Users/drbob.FSIDOMAIN/Desktop/TT-Safety-Cabinet-Performance.pdf

- Flammable Liquids Storage Cabinets, Part 2 of 2, Bob Benedetti, Principal Engineer, Flammable Liquids, NFPA. Campus Fire Safety eNews Zone, p8, 2011