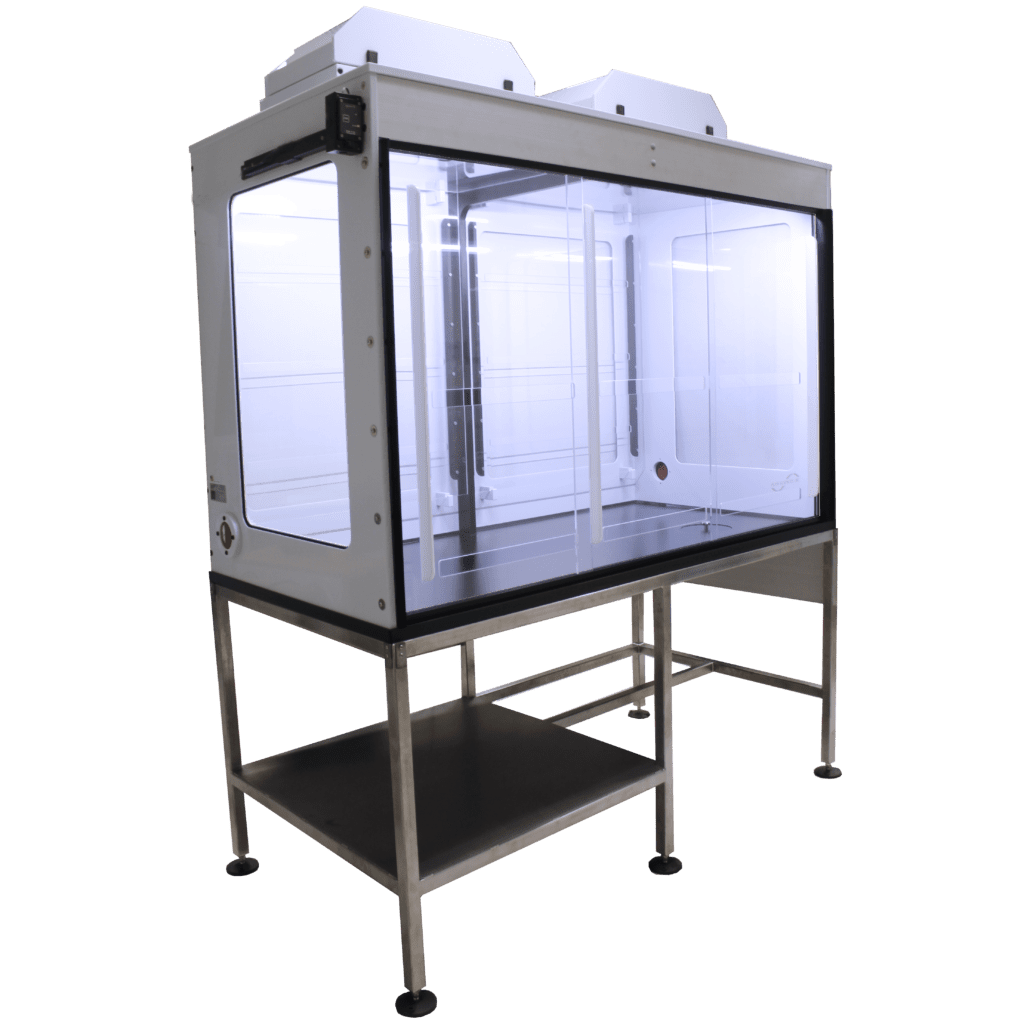

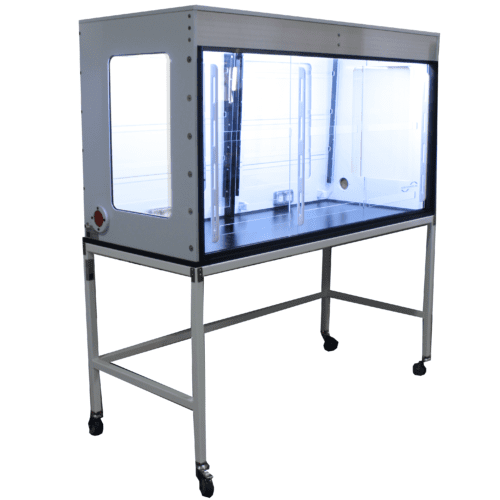

Retsch Mettler Sieving and Weighing Enclosure with Ezi Dock designed to provide personnel protection during weighing operations requiring sieving and safe discharge. Personnel protection is provided down to a respiratory exposure concentration of 1000-5000 micrograms per cubic meter air (1000-5000 ug/m3). Accommodates space for efficient usage and process flow between a Retch AS 200 Series Sieve Shaker and a Mettler Toledo ME4001/04 Precision Balance. 4” diameter bottom-mounted Ezi-Dock CSV 4 facilitates safe discharging of processed product out of the enclosure. (3x) removable sliding doors facilitate loading / unloading of equipment and unprocessed product. Door rail is removable to allow for additional loading / unloading room when necessary.

Optimal orientation of equipment inside of the enclosure is the AS 200 Sieve Shaker on the left, Mettler Balance in the middle.

This orientation allows for ergonomic process flow towards the Ezi – Dock discharge port on the right.

Additional features include:

- (2x) top mounted filter housings with HEPA filtration features 5.88” exhaust port for connection to house exhaust system

- 3” diameter rubber membrane iris port on right side facilitates entry/egress of equipment cables and cords

Dimensions:

External Width: 72.00”

External Depth: 38.60”

Internal Height: 44.69”

FSI Category 6-7