Noble Metal Bulk Powder Blending Workstation designed to provide personnel protection from metallic powder substances down to a respiratory exposure concentration of 100-1000 micrograms powder per cubic meter of air (ug/m3) during ball milling operations entailing the processing of 20 kilograms (kg) powder or less. Designed to provide this level of containment at an [operation] frequency of 6 hours per week.

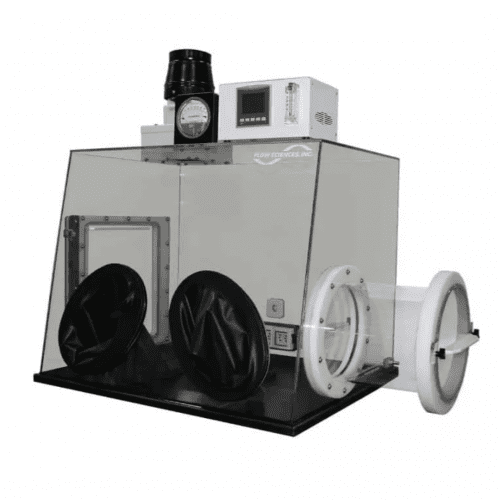

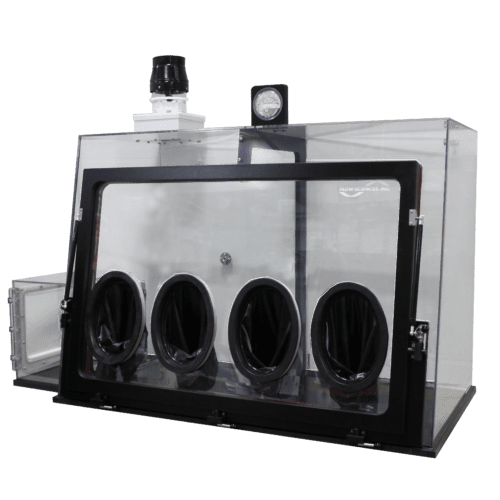

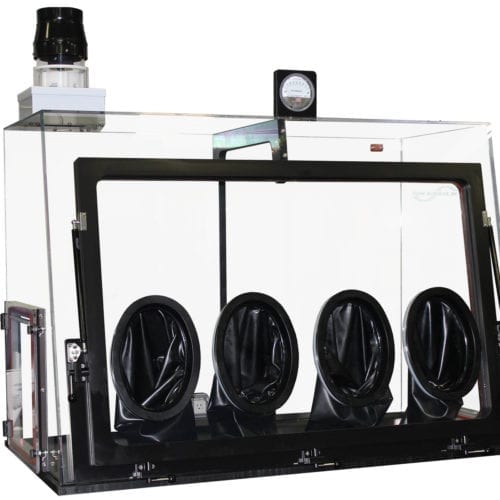

Two (2x) fan / filter housings with Dual-HEPA filtration isolates powders from personnel by way of negative-pressure containment. Minihelic gauge displays real-time display of differential pressure between the inlet side of the primary (first) HEPA filter and the surrounding [ambient] environment.

20” bulk powder cutout provides the utility of loading containerized product (e.g. 10-30 gallon drum or carboy) into the enclosure. On interior left side, a 304-grade stainless steel recess(*) facilitates the optimal ergonomic working height for tasks requiring the ball mill.

Stainless steel ADA(+) table allows the user to adjust the working height the workstation to meet their needs.

(+) stainless steel table complies with guidelines within the Americans with Disabilities Act of 1990 (ADA)

Additional features include:

- Blank acrylic port on left and right sides for optional retrofitting of disposal port (e.g. FS2070 or FS2079) or Pass-thru(^)

- FS1650 alarm which provides audible and visible alarms when its sensor detects that face velocity is less than specified (measured in linear feet per minute; lfpm)

(*)stainless steel recess is removed and shipped in a shipping container separate from the enclosure itself

(^)please call our toll-free number and ask for technical support for additional details

Dimensions:

External Width: 64.75” [1631.95mm]

External Depth: 30.00” [762mm]

Internal Height: 26.26” [667mm]