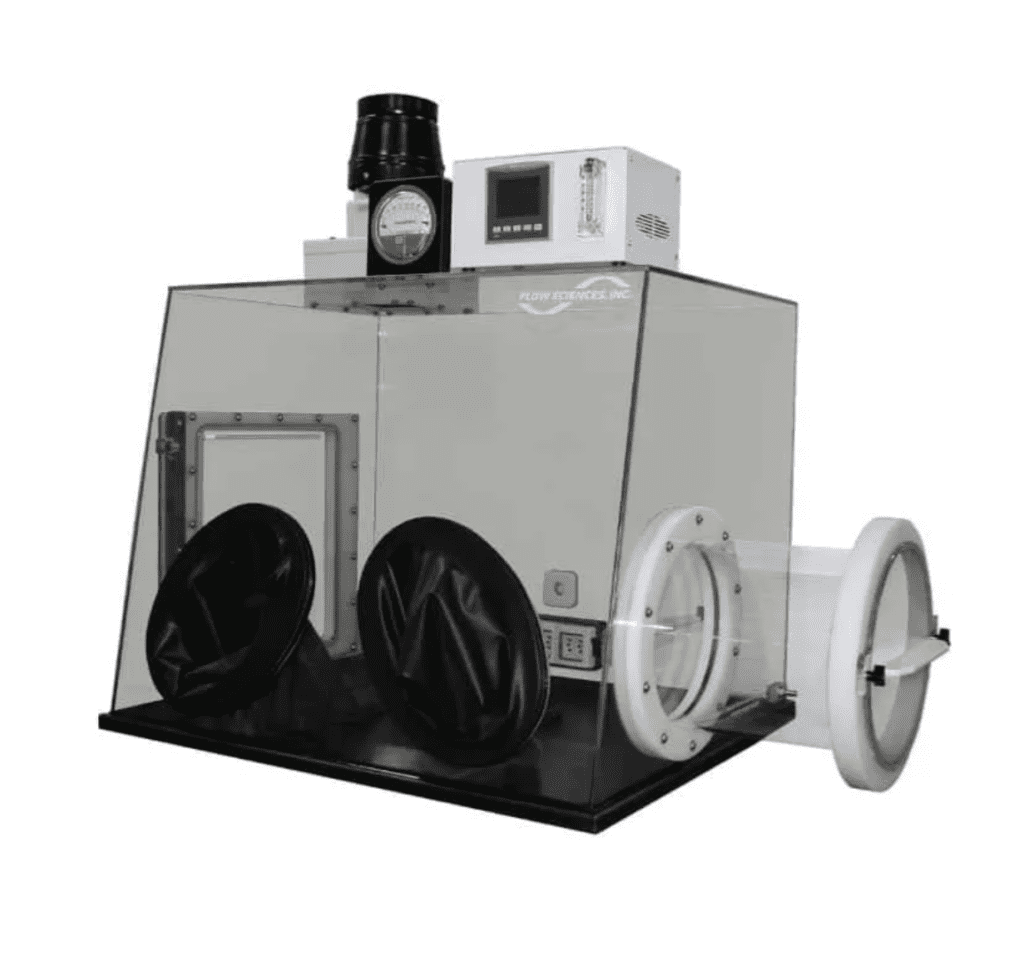

Nitrogen Purge Enclosure with R232 Connector designed to provide product protection during operations involving the manipulation of active pharmaceutical ingredients (API) sensitive ambient oxygen and relative humidity ( RH ) conditions. Enclosure features include acrylic superstructure, 10” diameter sealed pass-thru, and NEMA rated two gang covered modular outlet for electrical power connections. R232 connector rear wall allows for serial connection between interior and exterior of enclosure. Exhaust port on top of enclosure includes 8” x 8” x 3” HEPA filter for filtration of exhaust air leaving unit interior.

An electronically-actuated lift table, compliant with American with Disabilities Act of 1990, allows for user adjustment of table height by pressing a button on a panel.

Additional features include:

- 14” x 16” access door for ergonomic loading/unloading of equipment and containerized product

- Features FS1501 hi – flow Nitrogen Controller to control flow of nitrogen shielding gas (to prevent unwanted oxidation of product)

- Thimble connection which rests on top of exhaust port – allows for connection to house exhaust facilitates makeup air during nitrogen purge cycle

- 0-1.0” WC (water column) Magnahelic gauge displays measurement of pressure differential between the environments exterior and interior to containment zone

Dimensions:

External Width: 47.75”

External Depth: 26.00”

Internal Height: 28.00”

FSI Category 4-5