DESCRIPTION

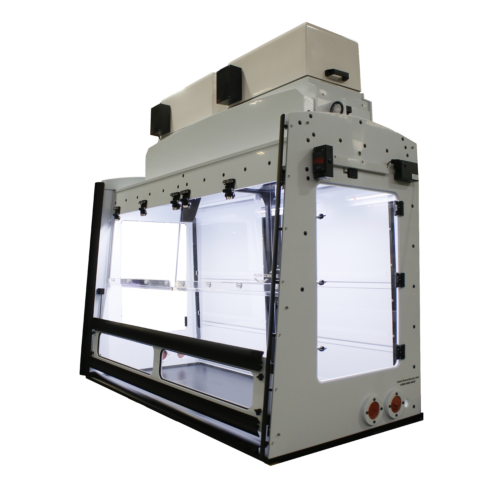

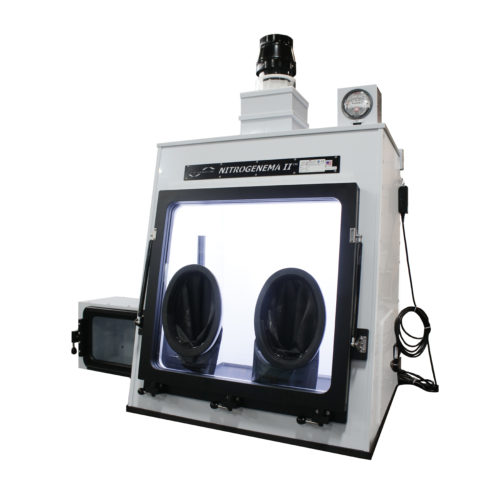

For containing vacuum oven where pressure and heat must be controlled for drying, curing, vacuum embedding, and plating applications. Enclosure features an aluminum frame, black phenolic base, two Ezi-Dock systems, and acrylic walls with access door for viewing and working with application. Dual top-mount filter and fan with BIBO and alarm system for monitoring laminar flow.

Size:

78” Exterior Width

50” Exterior Depth

27” Interior Height

PERFORMANCE TESTING

Performance is paramount in the safety industry. Through consistent design quality and expert manufacturing, Flow Sciences’ units perform. With surrogate powder testing both in our facility as factory acceptance testing (FAT) and at the customer facility as site acceptance testing (SAT), we consistently exceed our customers’ containment targets and goal expectations.

FLOW SCIENCES CONTAINS. FLOW SCIENCES PERFORMS.

Containment Target : 500 ng/m³

Surrogate Powder Testing Result : 4 ng/m³

Equipment : Balance, Oven

Operation : Simulated Drying, Bulk Transfer

Test : Naproxen Sodium – 3 x 500g