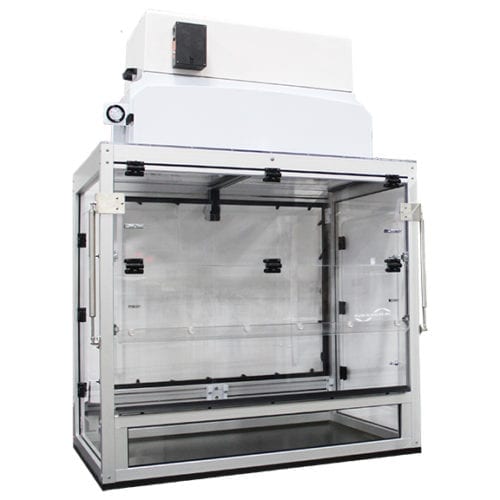

Bulk Powder Transfer to Weighing Station designed to provide personnel protection during bulk powder weighing operations. Attenuates respiratory exposure to Highly Potent Active Pharmaceutical Ingredient (HPAPI) contaminants down to a breathing zone concentration of 1 microgram per cubic meter (1 ug/m3). Features Top – Mounted Dual-HEPA filtration with Bag-In-Bag-Out (BIBO) filter replacement functionality, blanked port on left and right sides for optional retrofitting of 2070 waste chute. 20” internal diameter (ID) cutout for ingress of a bulk powder container (e.g. drum, carboy, etc.); includes black phenolic cover to retain containment when cutout is not in use.

4” sanitary fitting with included clamp and cover facilitates product charging and/or discharging. Sanitary fitting facilitates connection to compatible pharmaceutical packaging equipment (e.g. compatible EziDock products)*.

Black phenolic resin base dished to contain accidental spill of product. Switch-actuated LED lighting provides optimal view across the workspace.

*Sanitary fitting requires assembly

Additional features include:

- Integrated airflow alarm alerts the user when face velocity is below the setpoint calibrated by the certifier

- Minihelic pressure gauge displays real-time pressure differential between the ambient environment and the outlet side of the Primary HEPA filter (0-1 in. H2O)

Dimensions:

External Width: 59.75” [1518mm]

External Depth: 30.00” [762mm]

Internal Height: 26.90” [683mm]