Abstract

Engineering is a process to develop a design to solve a problem. In the world of containment engineering, careful premeditation is important to the completion of a successful engineering project. Flow Sciences aspires to inspire caution when making deductive decisions during the design of a containment engineering solution. The following list of ten selected mistakes, fallacies, and biases are intended to provide the reader with insight throughout their containment engineering projects:

1. Improper diagnoses of an issue resulting in an improper solution.

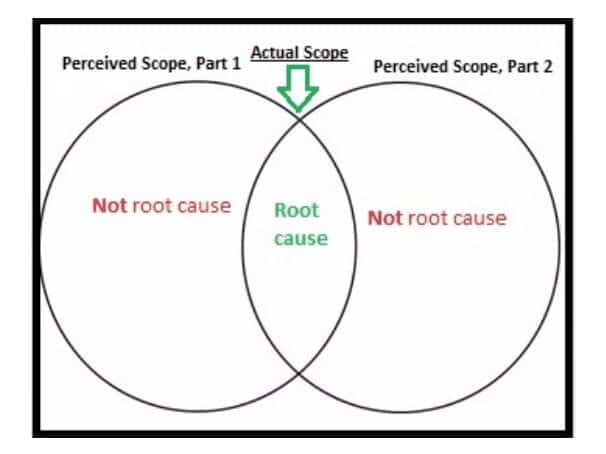

Occasionally, the scope of the actual problem is misdiagnosed. Once actions are taken in accordance with the perceived scope, the problem is likely left unresolved. This concept is explained in the visual Venn diagram below:

While the perceived scope may share aspects with the actual scope of the problem, the actions the engineer takes towards resolving the issue may partially solve the problem, not solve the problem at all, or exacerbate the issue.suds

2. Failure to understand financial limitations of the project.

If the engineer fails to understand the financial limitations of a project, he or she may design a solution that is cost-prohibitive or infeasible for the consumer to purchase and/or use.

3. Lack of awareness of the solution’s application.

To successfully engineer a solution for a complex process, one must have comprehensive understanding of the application for the solution that is being created. To start, try using the “Four Y’s and an H” approach: Who, What, When, Where, and How….from the start of the project all the way through to the end.

4. Lack of knowledge of the consumer’s support infrastructure.

For example; if an engineer were to design a containment solution which consumes a quantity of electrical energy exceeding the consumer’s energy budget allocation, the containment solution would likely be an irrational solution for the consumer.

When designing a containment solution for a consumer, it is critical for the designing entity to understand the limitations of the consuming entity’s resources. Ideally, the designing entity should produce a solution for the consumer which does not exhaust the consumer’s communication, labor, power, transport, or water resources at an inordinate rate. The engineering entity should ascertain the consumer’s average conditions of resource availability and apply it towards its design.

5. Lack of awareness of the potential impact of the materials that you are trying to contain (from storage to process to exhaust)

How do materials involved in the process interact with the surrounding environment, from “cradle” to “grave”? Does the material switch between phases of matter (e.g. gas to a liquid to a solid)?

6. Being unaware and disinterested in the time frame (from quote to delivery).

When the engineering entity is physically isolated from the consuming entity, communication is critical to achieving a successful transaction. If the designing fails to properly assess a project’s level of complexity prior to devoting time and resources towards it, the engineering entity may not complete the project on time or design/produce an insufficient solution.

Additionally, urgency for project completion may increase as time passes. If the engineering entity is unaware or disinterested in maintaining communication with consuming entity, the likelihood of customer dissatisfaction increases.

7. Unawareness of who/how many people will be operating the equipment that is being designed.

In some scientific applications, it may appear possible that the process can be completed with a number of persons less than an amount of persons feasibly, efficiently, and successfully complete it. Operating under the assumption that your solution will be utilized by a consumer of average stature, height, and health could also be detrimental to your customer’s satisfaction

8. Lack of foresight and knowledge of how well the design will interface with other elements of their system.

Another cognitive bias that could negatively impact your project is not considering the environment surrounding your solution’s final location. Without an idea of the room or area in which your solution is going to be used, you may receive an unexpected or catastrophic result. For example, designing a large product without the capability to collapse and move through a doorway shortly before installation on-site.

9. Not understanding ergonomics of design (e.g. easy to clean).

Designing a product for a specific application has a broader scope than simply just the application itself. It is a good engineering practice to account for inconveniences or impossibilities arriving from routine activities such as cleaning. For example, if the face opening of a containment enclosure is too narrow such that cleaning the rear of the enclosure is difficult, the operator may have a propensity to ignore that spot. The circumstances of this phenomenon presents the risk of product cross-contamination with the residue leftover from previous operations

10. Unfamiliarity with the regulatory requirements of the geographic area where the solution will be used.

When designing a product for a company located in another country, especially a developing country, it is important to review all laws and regulations that impact your project. Be sure to read any documents that may be referenced or adopted by the authoritative agency. It is a recommended practice to consult subject matter experts for input on the interpretation of laws which imply the usage of professional discretion.