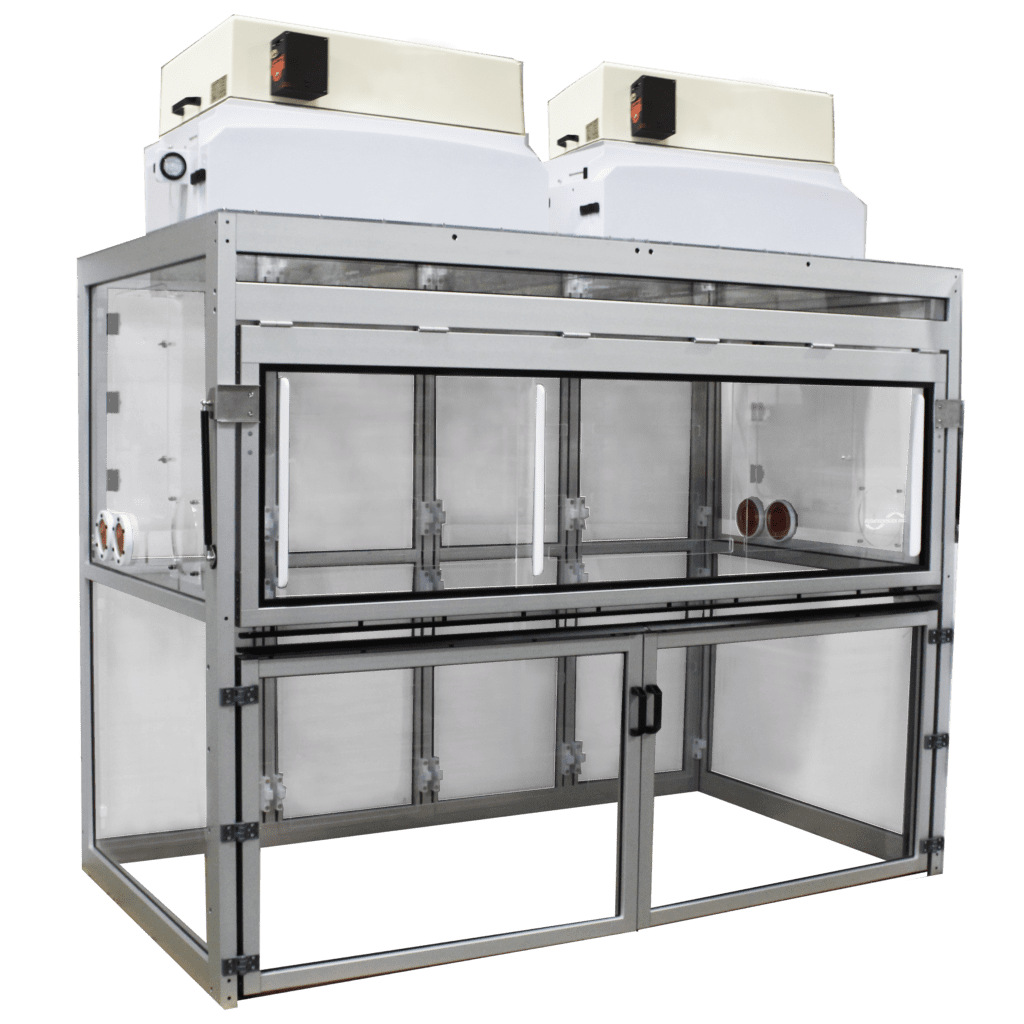

This Mix-to-Bed Drying Enclosure is designed for personnel protection. It reduces respiratory exposure levels to below 100-1000 µg/m3 (micrograms per cubic meter). This enclosure will contain Highly Potent Active Pharmaceutical Ingredients (HPAPI) during pharmaceutical manufacturing operations consisting of the following tasks: mixing, blending, milling, sheering, pressing, and bed–drying. An aluminum frame helps reduce weight and protects against corrosion.

This unit features two (18 in × 36 in) top-mounted fan/filter housings with Dual-HEPA filtration; Bag-In-Bag-Out (BIBO) filter replacement functionality allows the user to replace the primary HEPA filters without respiratory exposure to contaminants impacted into the used filter.

The front top door with gas shocks features three horizontal sliding doors; doors allow the user to access equipment and product inside the enclosure*. Two hinged doors on the bottom of the unit will enable the loading and unloading of equipment between process runs. Access doors (20” x 24”) on both sides allow quick access to the interior between each process run.

*containment provided with a maximum of 1 sliding door open at a time

Additional features include:

- (2x) minihelic gauges on each fan/filter housing display the real-time pressure differential between the exterior environment and the outlet side of the primary HEPA filter

- FS1650 airflow velocity alarm alerts the user when face velocity measurement falls below the set point

- FS2070 waste chute on the right side facilitates waste removal from the enclosure interior

Dimensions:

- External Width: 95.75” [2432.1mm]

- External Depth: 53.06” [1347.7mm]

- Internal Height: 72.98” [1853.7mm]