Centrifugal Evaporator Enclosure designed to provide personnel protection down to a respiratory exposure concentration of 50 ng/m3 (nanograms per cubic meter). Enclosure designed for a centrifugal evaporation operation where cytotoxic product could possible escape from vial during process or before the stopper is installed.

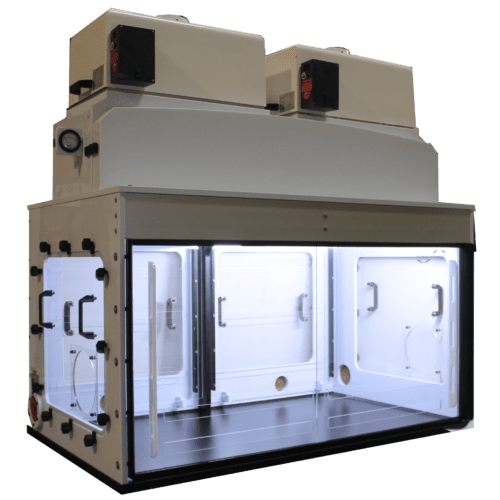

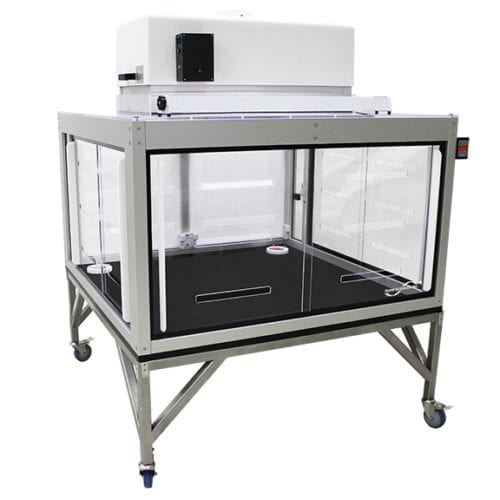

Features polypropylene superstructure and acrylic viewing panels. Top – mounted, Dual – HEPA filtrated fan/filter housing removes contaminants from enclosure interior. Bag-in-Bag-Out (BIBO) HEPA filter replacement functionality allows the user to replace filters without exposure to contaminant impacted on the old HEPA filter. Minihelic gauge displays real-time measurement of pressure differential between the outlet side of the primary HEPA filter and the surrounding environment.

(4x) removable sliding doors on front of enclosure facilitates easy access to enclosure interior, centrifugal evaporator, vials, and product. The operator is able to open up to two doors with retention of containment. 17.75”x 20.25” access door on left and right sides allows the user to load and unload equipment and vials. LED lighting provides optimal viewing across the workspace.

*containment provided with a maximum of two front doors open – containment not offered when one or both access doors are open

Additional features include:

- 1650 airflow velocity alarm alerts the user when the face velocity measurement is below the setpoint calibrated by the certifier

- 3” rubber membrane iris ports on rear-left and rear-right allow for ingress/egress of equipment cables and cords without breaching containment (2 iris ports total)

Dimensions:

External Width: 36.00” [914mm]

External Depth: 30.00” [914mm]

Internal Height: 28.82” [732mm]