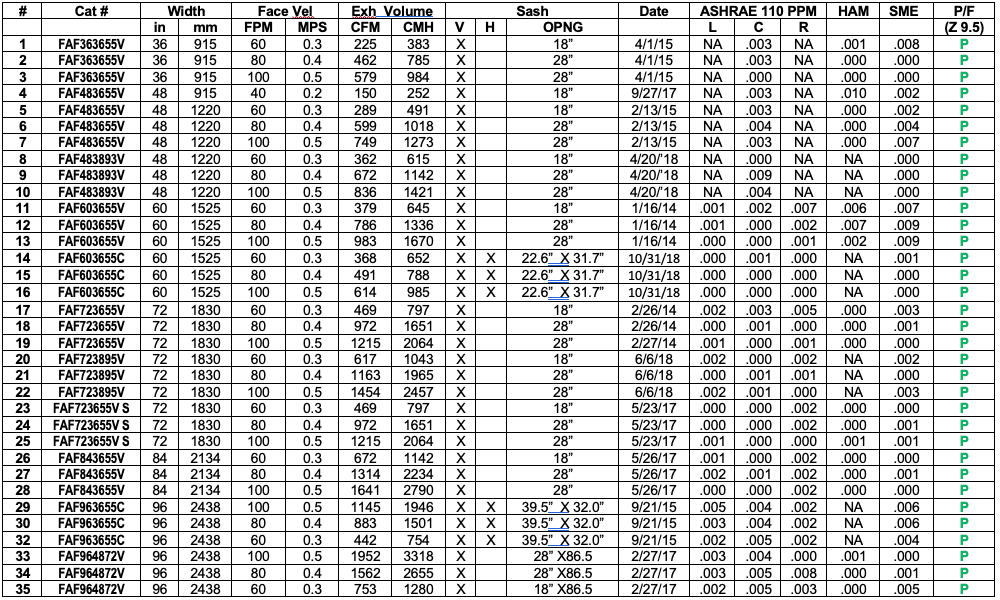

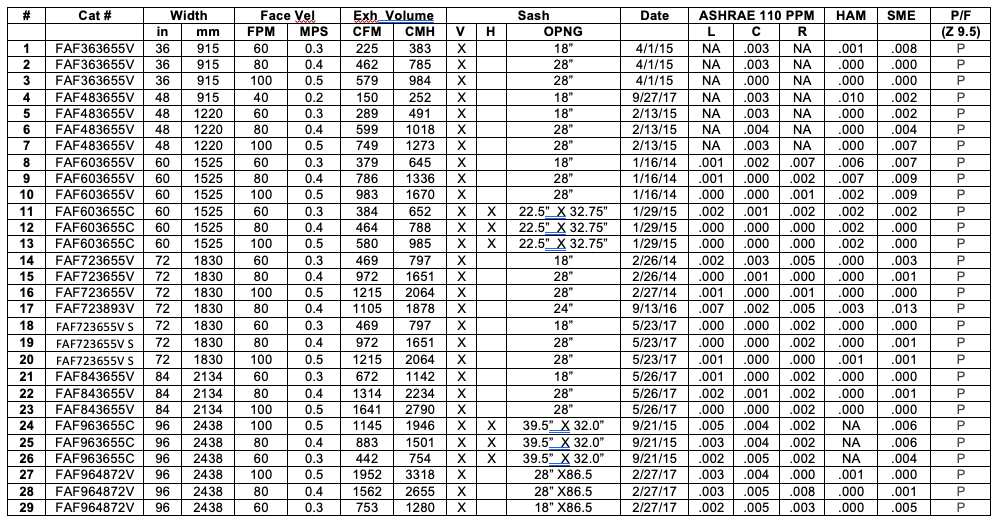

Over a period of time ranging from 11/6/2013 onward, the range of standard Saf T Flow Fume Hoods shown below were tested by Flow Sciences using the ASHRAE 110-1995 methodology. Details of the individual tests are available separately from Flow Sciences; total results are summarized below:

ASHRAE 110-2016 Saf T Flow Test Data Summarized by Volumetrics, Hood Description, and Catalog #:

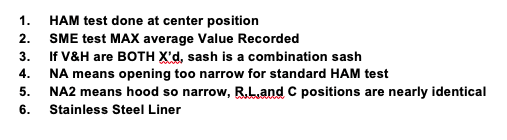

Procedures and Equipment:

In each test position, face velocities were established using a TSI thermal anemometer and a velocity grid specified in section 6.2 of the ASHRAE 110 standard.

The ASHRAE 110-2016 test procedure used employs a sulfur hexafluoride diffuser set at 30 PSI with a diffusion rate of 4 lpm. Tests were run with the mannequin in place for 5 minutes and SF6concentrations in the mannequin-breathing zone recorded.

An SME (sash movement effect) test was run for a total of two minutes and included opening and closing the vertical sash twice in 30-second intervals over the two minute run. Tests were run with the mannequin in place and SF6 concentrations in the mannequin-breathing zone recorded.

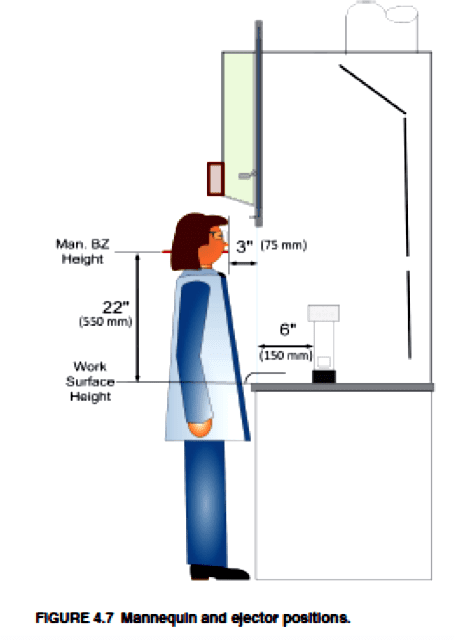

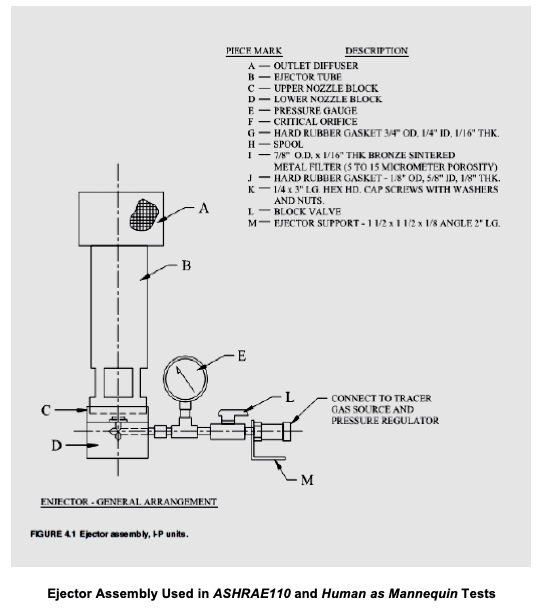

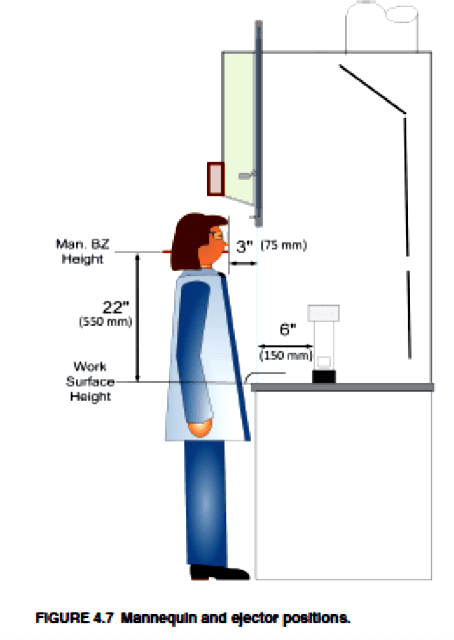

Relevant illustrations from the standard are shown below:

Approved ASHRAE Standard 110-2016 used as an overarching methodology

Ejector Assembly Used in ASHRAE110 and Human as Mannequin Tests

In each test position, face velocities were established using a TSI thermal anemometer and a velocity grid specified in section 6.2 of the standard.

The ASHRAE 110-2016 test procedure used employs a sulfur hexafluoride diffuser set at 30 PSI with a diffusion rate of 4 lpm. Tests were run with the mannequin in place for 5 minutes and SF6concentrations in the mannequin breathing zone recorded.

An SME (sash movement effect) test was run for a total of two minutes and included opening and closing the vertical sash twice in 30 second intervals over the two minute run. Tests were run with the mannequin in place for and SF6 concentrations in the mannequin breathing zone recorded.

Relevant illustrations from the standard are shown below:

The HAM Containment Test

While comprehensive dynamic tests are not a part of ANSI/ASHRAE 110-1995, it is evident that the low face velocity fume hood vulnerabilities might go unmeasured unless kinetic challenges are systematically introduced into our Safe-T Flow evaluation program.

The researchers decided to “borrow” a kinetic challenge test rather than design a hood to pass the lone and rather perfunctory dynamic sash movement test (SME Test) already in the ASHRAE 110 standard.

The Human as Mannequin Test

Funded jointly by Lawrence Berkeley National Laboratory and the California Energy Commission in 2005, the ECT group investigated kinetic challenges to low velocity fume hoods by developing a special test that used a human with an air sampler in front of a fume hood manipulating equipment in a specifically defined manner.1

For this adapted version of the HAM test, the researchers placed a breathing zone monitor on a tripod stand so it and the analysis equipment would not be jarred by the moving operator. Final array is shown below in Photo #1. The HAM tests involve conducting a series of choreographed activities using objects located within the hood. The objects consist of two 100 ml measuring cups, a 100 ml scoop, and a spatula.

The modified timed sequence of activities follows the layout shown in Photo # 1

- Stand at hood opening with arms to side.

- Insert and remove hands and arms

- Move objects #1 through #4 from six inch line to twelve inch line

- Exchange position of objects. (1 to 2, 2 to 3, 3 to 4, and 4 to 1)

- Transfer liquid from scoop #1 to scoop #2.

- Place spatula in empty cup.

Each sequence of activities is conducted over a period of approximately 70 seconds

Conclusion:

All Flow Sciences Saf T Flow fume hoods pass ASHRAE 110-1995, using criteria set forth in ANSI/AIHA Z 9.5, Section 6.3.7. A containment level of 0.050 PPM must be achieved in each test to pass, using the pass-fail level of 0.050 PPM established in AIHA Z 9.5; all data from all tests are much lower than this!

ASHRAE 110-2016 Saf T Flow Test Data Summarized by Volumetrics, Hood Description, and Catalog #:

Photos of Hoods under Test