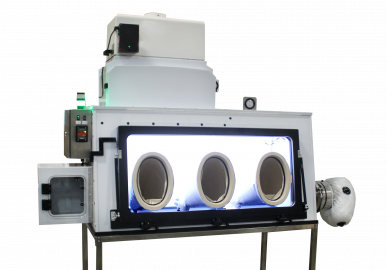

Lateral Flow Glovebox Workstation™

Lateral Flow Bio Containment Isolator (LFBC™)

For HPAPI/API Processing

The Glovebox Workstation is a sealed enclosure with a side-mounted HEPA inlet filter. It can provide containment for toxic applications using API/HPAPIs that need higher safety standards than an open-face enclosure. Engineered controls, such as door interlocks, assist in preventing containment loss. Third-party testing has proven exposure to be below 30ng/m³, dependent on application and quantity*.

Process

The Glovebox Workstation can contain processes including the weighing, dispensing, dissolution, compounding, and handling of APIs.

Containment

This unit can contain down to nanogram levels and varying OEB levels, depending on application and quantity.

Design

Provides adequate containment for a variety of lab equipment. Including balances, ovens, FTIR, sieves, and more

Benefits

Applications

This glove box is ideal for diverse lab OEB/Ls. Designed for HPAPI/API applications. Suitable for various lab requirements.

Structural Materials

Made of white polypropylene with acrylic panels. A chemically resistant phenolic base included. Designed to contain spills effectively.

HEPA Filtration & ISO 5 Interior

Unit features a side-mounted 4” HEPA inlet. Cleans incoming and exhausted air. Ensures ISO 5 clean working standards.

Side/ Transfer Port

Offers side-port with multiple universal options. Including RTP port, waste chute, and more. Ensures safe material transfer in/out.

Sanitary Fittings

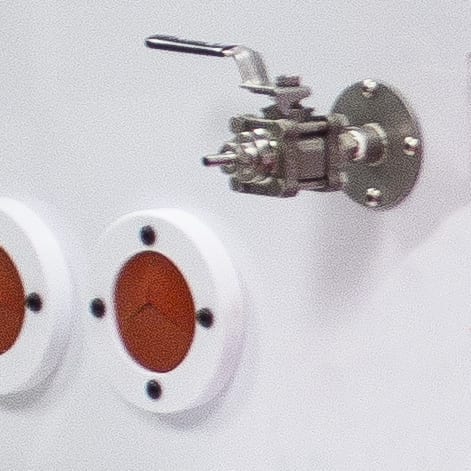

Features two standard sanitary fittings. Coupling for various powder transfer systems. Placement flexibility: base/worktop or side panel.

Standard Sizes

Options include 5′, 6′, and 7′ widths. Units have 36” depth and 24” height. Custom dimensions are available based on need.

Useful Videos

Additional Resources

SEARCH CONTAINMENT BY APPLICATION

Over the years, we built an inventory of unique enclosures engineered to handle specific tasks. To offer you a better experience we have gathered these enclosures on one page. Simply search by the task or equipment to find matching enclosures.

Over the years, we built an inventory of unique enclosures engineered to handle specific tasks. To offer you a better experience we have gathered these enclosures on one page. Simply search by the task or equipment to find matching enclosures.

Process

Weighing, dispensing, dissolution or handling of APIs and/or HPAPIs where personnel protection is required.

Containment

Reaches containment measured in nanogram levels and from OEB 3–5, depending on application and quantity.

Design

Provides adequate containment for equipment including balances, ovens, FTIR, sieves, and more.

Lateral Flow Bio Containment Isolator

Safety

The Glovebox Workstation provides containment for highly toxic applications using APIs, and HPAPIs, that need higher safety standards than an open face enclosure. Our engineered controls assist in the prevention of containment loss. Third-party testing has proven containment on these units to below 30ng/m³, dependent on application and quantity.

ISO 5 Cleanliness

The side mounted HEPA filter inlet creates a clean interior working environment that meets or exceeds ISO 5 for clean processing work.

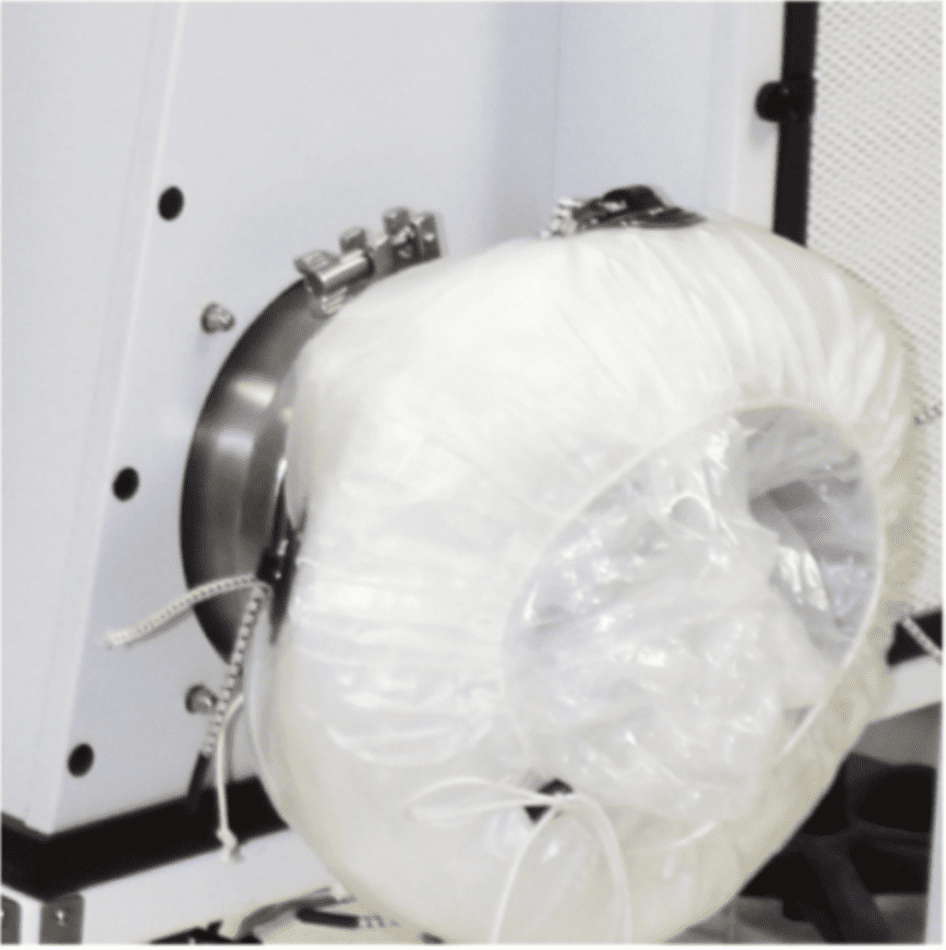

Universal Side/Transfer Port

Side port with universal options including double-safe waste chute, continuous liner, RTP port, and more, available through customization. (The side port and transfer port can be placed on either side.) The transfer port provides ingress and egress of materials into and out of the enclosure without exposing the interior environment to contamination.

Construction

This unit gives the option of using acrylic (EGP Series) or glass (EGG Series) for the viewing panels. The superstructure is built using polypropylene and the dished phenolic resin base is designed to contain any spills.

LED Light

An internal white LED light provides improved visibility inside of the enclosure with adjustable angles to direct light into the workspace. Also available in Amber LED.

HEPA Filtration

Equipped with a 4” inlet HEPA filter and 2 primary and 2 secondary 4” HEPA filters that can be recirculated into the lab or vented out through building exhaust.

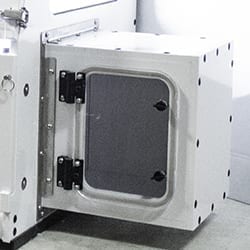

Front Lift Door

The glove ports sit in a front lift door that opens vertically to effectively load and unload equipment. This door is hinged for ease of use.

Standard Sizes

Available in 5’, 6’, and 7’ foot standard width options. All units are 36” deep and 24” of internal height. Customization available.

Popular Configurations

Have Questions?

Send us a message with the live chat feature or contact us using the online form so we can help answer your all questions.

Contact Our Experts

TaskMatch

SEARCH PREVIOUS

BUILDS BY APPLICATION

BAG-IN/BAG-OUT

(BIBO) Change-out

Build Options

| Product Type | Style | Material | Ext. Width | Ext. Depth | Internal Height | Base | Exhaust / Filtration | Voltage / Filter / Alarm | Options |

|---|---|---|---|---|---|---|---|---|---|

| E – Enclosure | G – Glovebox | P – Poly (Acrylic viewing panels) | 48" | 30" | 24" | A – Standard | B – Fab/BIBO | D – 110-120v 50-60Hz/HEPA Filter/Integrate Alarm | 0 – Pass Thru Left, Filter Right |

| G – Poly (Glass viewing panels | 60" | E – 4" Tri-Clover Male | G – Mesh Fan/BIBO | F – 220-240v50-60Hz/HEPA Filter/Integrated Alarm | 1 – Pass Thru Right, Filter Left | ||||

| 72" | F – No Base (must be purchased separately) | I – 110-120v50-60Hz/ULPA Filter/Integrated Alarm | |||||||

| J – 220-240v50-60Hz/ULPA Filter/Integrated Alarm |

Accessories

| Side Port Options | ||

|---|---|---|

| Blank Plate | No side port needed |

|

| Continuous Liner | Designed to eliminate cross contamination of powders, protecting the person, plant, and product. Long lengths of pre-packaged liners reduce operator labor. |

|

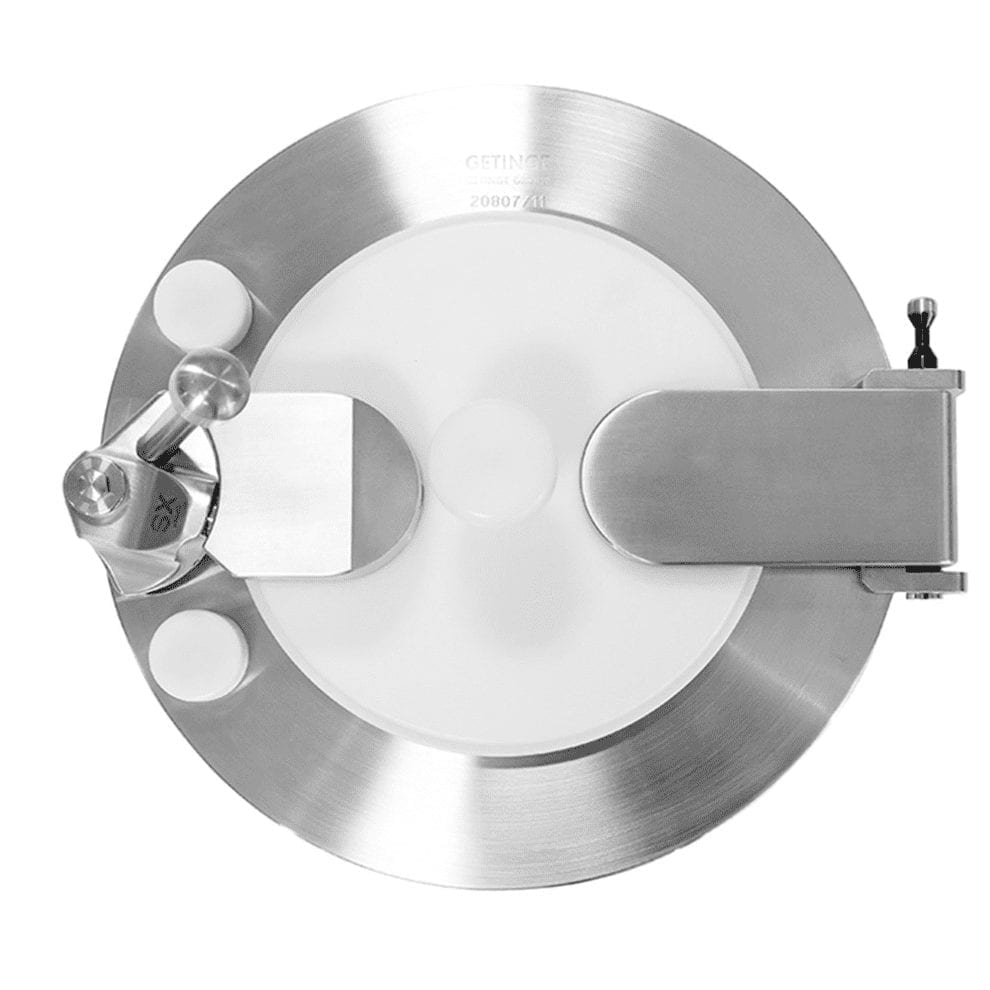

| RTP Alpha Port | Accommodates a 105mm RTP Alpha port for connecting various betas or other containers. |

|

| Transfer Box | Polypropylene construction with access door to move materials in/out of the enclosure. |

|

| Customized Master Port | The blank plate can be customized to install iris ports, services, transfer systems, and more. |

|

| Add-Ons | ||

|---|---|---|

| Berkshire Cleaning Kit | Contact Flow Sciences for kit description |

|