Dr. Bob Haugen

Director of Product and Technology Development

Flow Sciences, Inc.

Abstract:

We have already looked at accidents inside fume hoods and posed several questions that might rush through one’s mind directly after a fume hood fire erupts 1.

From this earlier paper referenced above and an additional literature search we will examine the following issues in this second paper:

- What construction and installation techniques must be observed while selecting and installing a fume hood that will reduce the chances of a fume hood fire spreading to the remaining lab space and possibly the entire building?

- If a hood fire starts, should fume hood fans be switched off? (Issue unresolved in first paper)1

- What kind of ductwork should be used for chemical fume hood exhaust?

The author reviews these key issues in the remainder of this paper.

Key Issues:

1) What construction and installation techniques must be observed while selecting and installing a fume hood that will reduce the chances of a fume hood fire spreading to the remaining lab space and possibly the entire building?

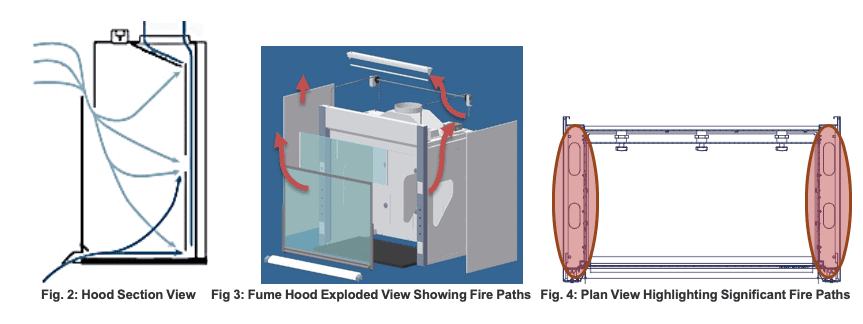

Any fume hood fire will interact with the room it is in. The suspended ceiling in such a lab is a key feature in determining how such a fire will spread. Flames may travel up through the fume hood into the duct system in this scenario. Let’s look at how such a ceiling is installed and what it is supposed to do during a fire.

Suspended ceilings made from fire-rated rectangular tiles are often used in lab construction as a way of retarding fire progression by preventing fires in a room from quickly spreading upward and affecting the room ceiling, which would accelerate the spread of fire to the floor above.

It has been found that such a ceiling must have all tiles in place to perform this function. Open rectangular spaces left during maintenance or replacement destroy the entire protective strategy. Once through such an opening, fire and heat can rapidly spread horizontally and upward thereby propagating the flame to the immediate floor above.

If the fume hood liner material is breached with either cracks due to heat or dislodged plumbing access panels, very bad things happen! The hood fire can channel up the “chimneys” formed by the space between the outer steel shell of the fume hood and the hood liner material into the suspended ceiling cavity.

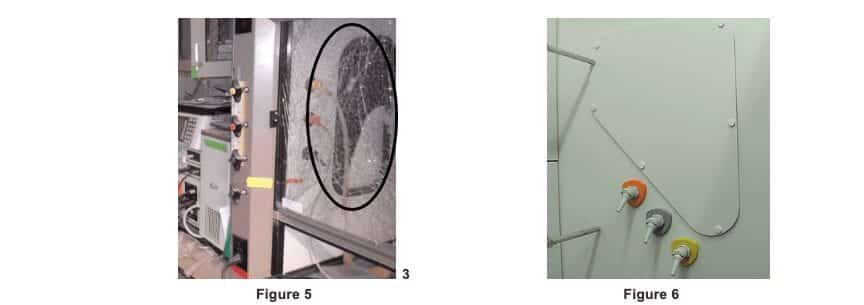

An actual dislodged access panel (Figure 5) is shown above. The panel is smaller than its circled opening and is fit into the cutout with a gasket. In this photo, the gasket has been dislodged by explosive force, causing the panel to fall through the opening, allowing a fire pathway upward. In figure 6, a screwed-in panel larger than the covered opening resists explosive displacement.

In no case should interior fume hood plumbing access panels be smaller than the opening they cover. Gasketed material used to “seal” such openings should be avoided. More generally, access panels and gaskets should never be manufactured from a material which melts or can be distorted into a shape that can fall or be pushed through the hole they are covering.

Once a fire breaks through the hood wall liner material or access openings, it is free to move upward. Figure 7 shows two hoods soffeted into a suspended ceiling; an open gap above this hood will allow flames to enter the suspended ceiling cavity, ruining its effectiveness. A finished suspended ceiling to the wall is preferred construction! (figure 8) This fume hood installation has a clear separation between ceiling and hood superstructure, preserving the fire retardant characteristics of the finished ceiling.

If a hood fire spreads into this suspended ceiling cavity, it will move horizontally relatively undeterred. Since many labs have “walls” that terminate at the suspended ceiling, these areas are often vast and untidy fire throughways.

NFPA 45 Section 6.1.1.1 requires sprinkler systems in all NEW labs in accordance with NFPA 13. NFPA 13 states complete suspended ceilings should have sprinklers below such a ceiling. Incomplete ceilings, sometimes called “cloud ceilings”, may require sprinklers above and below the suspended ceiling line. Differentiation here is a bit unclear. Obviously, the area above a ceiling should be properly protected by sprinklers, in a manner consistent with NFPA 13 and local code.

The general vulnerability of suspended ceiling design was summarized by Francis L. Brannagan 5 as follows:

“In the first edition of Building Construction for the Fire Service (1971), I pointed out the basic deficiency of this system: the loss or failure of one tile exposes the entire floor to the fury of the fire below. I was told by a U.S. General Services Administration (GSA) fire protection engineer that the GSA never built a building for its own account with this type of construction.”

To summarize, laboratory suspended ceiling design should not include an opening for the fume hood superstructure to “fit through”. A complete suspended ceiling should always be placed above the entire lab, including the fume hood superstructure. Such a complete suspended ceiling will resist flames traveling from the inner containment area of a fume hood into the painted steel outer shell where they can easily “chimney up” past the fume hood superstructure.

For this reason, contractors should never use the fume hood superstructure as an anchoring point for a suspended ceiling in a lab. A gaping hole above the hood in the suspended ceiling results. This condition obviously exacerbates the spread of any fume hood fire through the suspended ceiling space.

There is at least one very notable example of how suspended ceiling spaces can become involved in quickly spreading lab fires. It happened in 2012 in Tulsa Oklahoma:

“The historic Barnard School Building went up in flames about 5 a.m. on September 5. When firefighters arrived, the building exploded, rocking midtown Tulsa and sending eight firefighters to the hospital.

After a week-long investigation, officials said the fire and explosion resulted because of “construction related to the installation of an exhaust vent in the lab area,” according to a news release.

The explosion occurred because the fire had been smoldering in the void between the chemistry lab ceiling and the floor of the room and hallway above, the release said.

Investigators said the fire migrated north under the hallway floor into the classroom, and the crawl space below where it vented from the classroom window. The resulting smoke explosion or “backdraft” occurred when oxygen was introduced into the area by the firefighters entering the room to extinguish the fire.”

News 6 Tulsa 14 September 2012.

2) If a hood fire starts, should fume hood fans be switched off or fire dampers be activated? (Issue unresolved in first paper)1

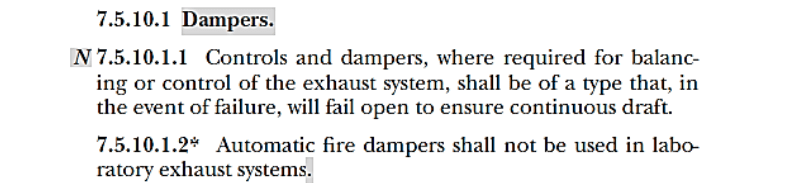

First, we go to the latest NFPA 45 standard to determine if dampers should be automatically closed in hoods in the event fire is present in the duct:

NFPA 45 clearly prohibits fume hood fire dampers. In addition, a clause was added this year (7.5.10.1.1) stating flow control dampers added for other reasons in a fume hood exhaust duct must fail open.

On the issue of exhaust ventilation being turned off in case of a fire, NFPA 45 section 7.5.11 states:

While NPPA does not state why this requirement is so strongly set forth (in all cases shall is used), there are many well-known realities in play here:

- Stopping flow through a fume hood exhaust duct during a fire would insure all the combustion byproducts would erupt back into the lab area. (carbon monoxide, aromatic hydrocarbons, soot, other “bad actors”.

- In a hood fire, a functioning fume hood exhaust offloads heat as well as fumes. In the short term, an exhaust cutoff would increase the temperature inside the containment cavity assuring faster compromise of this structure.

- Escaping lab personnel need fresh air, which will be drawn into the lab in direct proportion to the exhaust that is drawn from it.

- To some degree, this question has almost become academic as fewer and fewer fume hoods are specified with fan on-off switches in the first place.

Given these issues, we conclude fume hood exhaust shall not be switched off in a fire situation!

3) What kind of ductwork should be used for chemical fume hood exhaust?

Again NFPA 45 speaks, albeit equivocally, to this question:

While hood interiors and ductwork are limited to a flame spread <25, ductwork must also be compatible with conveyed materials (8.3.3.2).

If lab designers were hoping to be given specific help on duct type by NFPA 45, they would have been severely disappointed by section 8.3.3.2. Particularly in large projects with diverse labs, this rather vague section on duct compatibility assumes chemists all do the same thing and there is a duct type that is omni-resistant. Neither of these assumptions are true.

Ductwork made from different materials behave differently. Here are examples:

1) Stainless steel ductwork is great, except with halogen acids like HCl (one of the most common reagents).

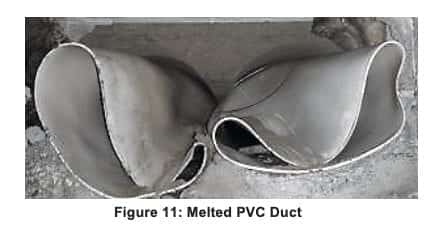

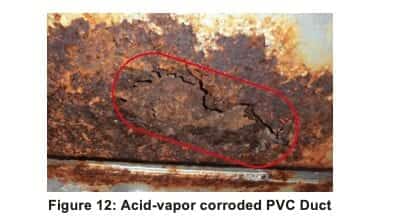

2) PVC ductwork is great for acidic fumes like HCl (g), but certain types soften at 250o

3) Galvanized steel ductwork (the least expensive option) maybe acceptable for milder applications unless corrosion scenarios become present when the quantities of exhausted corrosives are dramatically increased by some new application.

How can an Architect/Designer assure a building’s safety when ducts may cease to conform with section 8.3.3.2 of NFPA 45 as new chemists, projects, and missions change routinely used chemicals being exhausted into original ductwork within the lab building?

Flow Sciences always asks application questions of our customers exactly because of issues like these noted above. What is your application? How much reagent(s) are exhausted each week? Are you considering energy conservation by reducing exhaust volumes? What are the chances your applications will significantly change?

Obviously, when manufacturers ask such questions, we protect ourselves and our customer from receiving the wrong product for the application. Building-wide exhaust issues are always a much larger question generally abandoned at the doorstep of building maintenance. As VAV and other low volume technologies become retrofitted, further reducing exhaust flow for fume hood procedures, corrosive exhaust concentrations will increase. Ducts installed for more dilute fume concentrations may become severely challenged for this reason alone!

Conclusions:

1) From a fire safety standpoint, a well-designed fume hood must have a containment cavity built with materials having a flame spread < 25 using ASTM E84.

All interior access cutouts should be covered with liner material with a similar low flame spread. Side wall interior access panels must be larger than the cutout and held in place with screws rather than gaskets, unless said gasket will not burn, melt, or come loose in a fire.

In addition to this precaution, the hood must never be installed as part of the suspended ceiling support system. A suspended ceiling should go above a fume hood and never through it!

2) A fume hood exhaust system should never be shut down during a hood fire event. Dampers should not be closed. Not automatically, not manually.

NFPA 45 is clear on this issue. The effects on lab personnel and room fire Involvement rate of disabled exhaust systems are typically worse than if the system is allowed to run.

3) Chemical exhaust ducts should have an ASTM E84 flame spread < 25.

While any duct must be compatible with materials being exhausted, facilities should record the duct types used so when fume hood applications change with time, new uses may be checked for compatibility with the existing ducts. Where necessary, non-zero flame spread ductwork must be fire shielded as described in NFPA 45. Commonly used duct materials are stainless steel, PVC, and galvanized steel. Each material has limitations and advantages which may be reviewed with respect to lab exhaust use profiles.

In summary, we have seen that fume hood fires must be seen in the context of what goes on above the hood as well as in it. Fans, ductwork, and the maintenance of a complete suspended ceiling all play a role in preventing serious laboratory fires.

Footnotes:

- Fume Hood Fires, Robert Haugen, Flow Sciences White Paper, 8/2018, https://flowsciences.com/fume-hood-firessmoke-heat-and-finally-illumination/

- Making Sense of Laboratory Fire Codes, Richard Palluzi, AIHCE Journal, pp 54-58

- University of Hawaii Fined $115,000 for lab explosion, C&EN News, Sept 29,2016

- Overview of the International Mechanical Code, International Code Council, 2018, https://www.iccsafe.org/products-and-services/i-codes/2018-i-codes/imc/

- https://www.fireengineering.com/articles/print/volume-158/issue-4/departments/the-ol-professor/suspended-ceilings.html, FRANCIS L. BRANNIGAN, SFPE (Fellow), the recipient of Fire Engineering’s first Lifetime Achievement Award, has devoted more than half of his 63-year career to the safety of firefighters in building fires. He is well known as the author of Building Construction for the Fire Service, Third Edition (National Fire Protection Association, 1992) and for his lectures and videotapes. Brannigan is an editorial advisory board member of Fire Engineering.

- https://www.huffpost.com/entry/chemistry-fire-video-lab-sprinklers_n_3314085

- Flow Sciences floor mount fume hoods

- https://publicsafety.tufts.edu/ehs/fire-safety/

- http://www.expertconstructioninc.com/acoustical.html

- This is a photo of the Flow Sciences Saf T Flow fume hood sidewall access panel. Other manufacturers emulate this design.