Custom Design

Flow Sciences’ team of containment experts bring decades of custom design expertise, with consistent compliments of creativity and adaptability, to global technological developments and processes.

Our sales, engineering, and project management staff begin by creating a unified understanding of every customer’s process and goals through the completion of the Custom Quote Request Form.

Many of these custom projects are equipment specific, and focus on the localized containment of the procedure while providing personnel and/or product protection. If you are working with a specific piece of equipment, please let us know. Our design history has led to many custom solutions created for equipment that is highly likely to be similar or exact to your specific equipment.

With surrogate powder testing both in our facility as factory acceptance testing (FAT) and at the customer facility as site acceptance testing (SAT), we consistently exceed our customers’ containment targets and goal expectations. We have significant documentation of the superior performance of our products. For more information, please contact us.

FLOW SCIENCES SERVICES

CONSULTATION

Flow Sciences’ team of containment experts are challenged with providing solutions for complex applications. These projects are mostly equipment specific, and focus on the localized containment of the procedure while providing personnel and/or product protection. Pairing with a Flow Sciences Containment Consultant allows users direct help with developing SOPs and GLP training.

DESIGN

Flow Sciences has championed the industry in airflow for over 30 years. Holding numerous patents in airflow safety and design, Flow Sciences continues to use advanced engineering controls and airflow concepts to maintain the best personnel and/or product protection in the industry.

MANUFACTURING

Performance is paramount in the safety industry, and through consistent quality design and expert manufacturing, Flow Sciences’ units perform.

TESTING

Performance is paramount in the safety industry. Through consistent design quality and expert manufacturing, Flow Sciences’ units perform. With surrogate powder testing both in our facility as factory acceptance testing (FAT) and at the customer facility as site acceptance testing (SAT), we consistently exceed our customers’ containment targets and goal expectations.

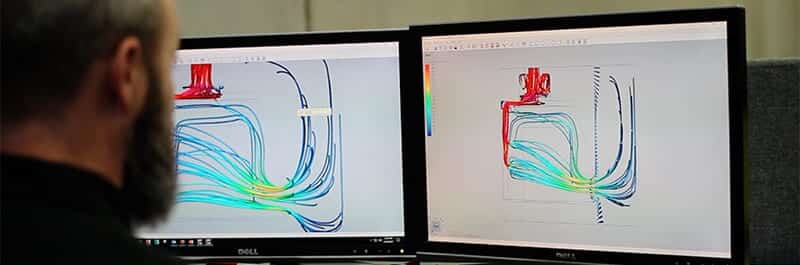

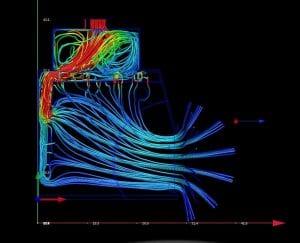

Enclosure Design: The Advantages of CFD

Computational Fluid Dynamics (CFD) is the study of fluid dynamics using sophisticated computing technology. Computational Fluid Dynamics uses or solves the governing equations of fluid or gas flows to predict the characteristics and the structure of a flow field. The most important feature or advantage of using CFD in the design process is the ability to see airflow. CFD allows the use to see the results of engineering design more effectively than in the real world. The effects of minute features in the designing process can be seen and compared using CFD which cannot be done in an otherwise efficient manner. Another added advantage of using CFD is the repeatability of the results.

Flow Sciences uses CFD in the design process in order to concentrate and study the effects of changes in airflow (large and small) in the enclosure design. Any changes to an enclosure’s design affect the airflow structure inside the enclosure and FSI’s goal is to maintain stable airflow that improves containment while also providing a low turbulent atmosphere that allows sensitive equipment to perform properly and minimize any potential product loss. With CFD we have the advantage of evaluating the performance of the enclosure even before it is built, and then verify those results in our testing lab. This results in our clients receiving enclosures that have proven performance.

Engineered and Manufactured in the Port City of Wilmington, North Carolina, USA

Top Containment Performance and Technology with Over 30 Years in the Industry and 11 US Patents and Counting.

FSI is ISO 9001:2015 Certified for Quality Manufacturing and Product Performance