Ensuring compliance with USP <800> standards is crucial for the safety and well-being of both personnel and the environment when handling hazardous drugs. Flow Sciences, Inc. leads the way with innovative solutions like Containment Primary Engineering Controls (C-PEC) and Containment Secondary Engineering Controls (C-SEC), designed to mitigate exposure and ensure controlled handling of hazardous drugs. With a range of expertly engineered products, including High-Efficiency Particulate Air (HEPA) filters, vented enclosures, and safety cabinets, Flow Sciences is dedicated to providing industry-leading containment systems that not only comply with but exceed USP <800> requirements

USP <800> Explained

Terms Applicable to USP <800> Standards:

c-pec

Containment Primary Engineering Control

A ventilated device designed to minimize worker and environmental hazardous drug exposure when directly handling hazardous drugs.

c-Sec

Containment Secondary Engineering Control

The designated room where the C-PEC is situated. It ensures the environment around the C-PEC remains controlled and secure.

HD

Hazardous Drugs

Pertains to the toxic powder or active pharmaceutical ingredient that is handled within specific containment measures, ensuring safety for both workers and the environment.

HEPA

High-Efficiency Particulate Air Filter

HEPA Filters are designed to capture and remove airborne particles, with at least 99.995% effectiveness.

ACPH

Air Changes Per Hour

Complete air replacements that occur within a Containment Secondary Engineering Control (C-SEC).

CVE

Contained Vented Enclosure

A specialized, vented containment enclosure ensures both personnel and environmental protection.

Class I BSC

Biological Safety Cabinet

A Class I BSC is a containment enclosure that safeguards both personnel and the environment.

CAI

Compounding Aseptic Isolator

Provides aseptic conditions while preparing sterile medications, ensuring personnel safety.

CACI

Compounding Aseptic Containment Isolator

Provides sealed aseptic conditions for sterile compounding, ensuring personnel AND product safety.

Requirements for Non-Sterile HazarDous Compounding

Ensuring Safe & Effective Practices

At Flow Sciences, we recognize the significance of adhering to the requirements in HD compounding. Our expertise and comprehensive range of solutions empower you to achieve the utmost safety, compliance, and efficiency. Count on us to be your partner in upholding the highest standards in hazardous drug handling.

C-PEC ventilation requirements depend on the application. It can be externally vented (preferred) or redundant HEPA-filtered in series. Examples: CVE, Class I BSC, CAI or CACI

C-SEC MUST be externally vented AND have at least 12 ACPH. Externally vented, ≥ 12 ACPH, Negative pressure between 0.01 and 0.03 inches of water column relative to adjacent areas. Requirements vary based on application.

Variety of C-PEC Options: Flow Sciences offers an array of C-PEC solutions, including our time-tested CVE, Class I Bio-Safety Cabinets, and Compounding Aseptic Containment Isolators. Among these, our CVE paired with Single or Dual HEPA filtration units (dependent on application) stands out as an efficient solution to USP <800> compliance.

Engineered Solutions

Recommended for USP <800> Applications

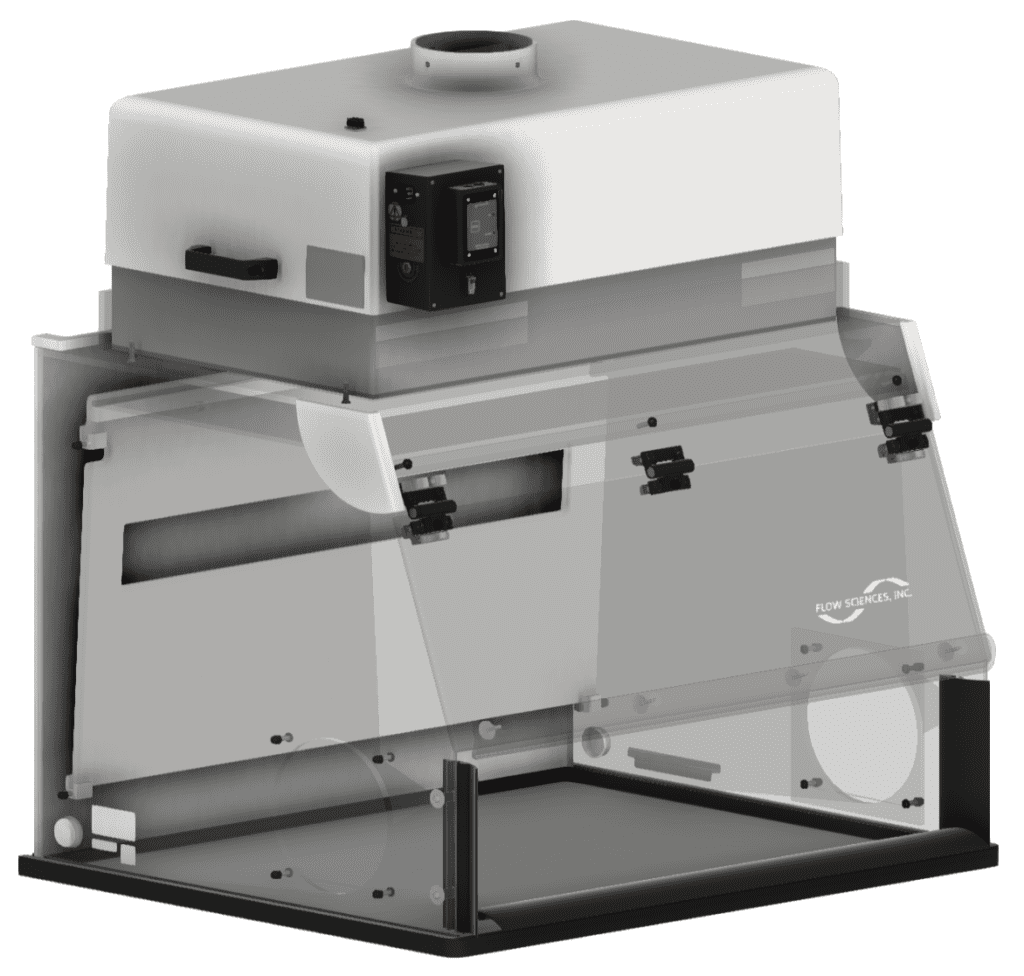

SINGLE-HEPA,

TOP MOUNT

NON-HAZARDOUS, NON-STERILE

Flow Sciences Contained Vented Enclosure with Single 4” HEPA filter and fan.

- Safe powder handling of hazardous drugs for personnel protection and reproducibility in sensitive application

- THIMBLE CONNECTION and VENT KIT required to connect CVE to the house exhaust system

- Stable airflow and NO VIBRATION on the work surface

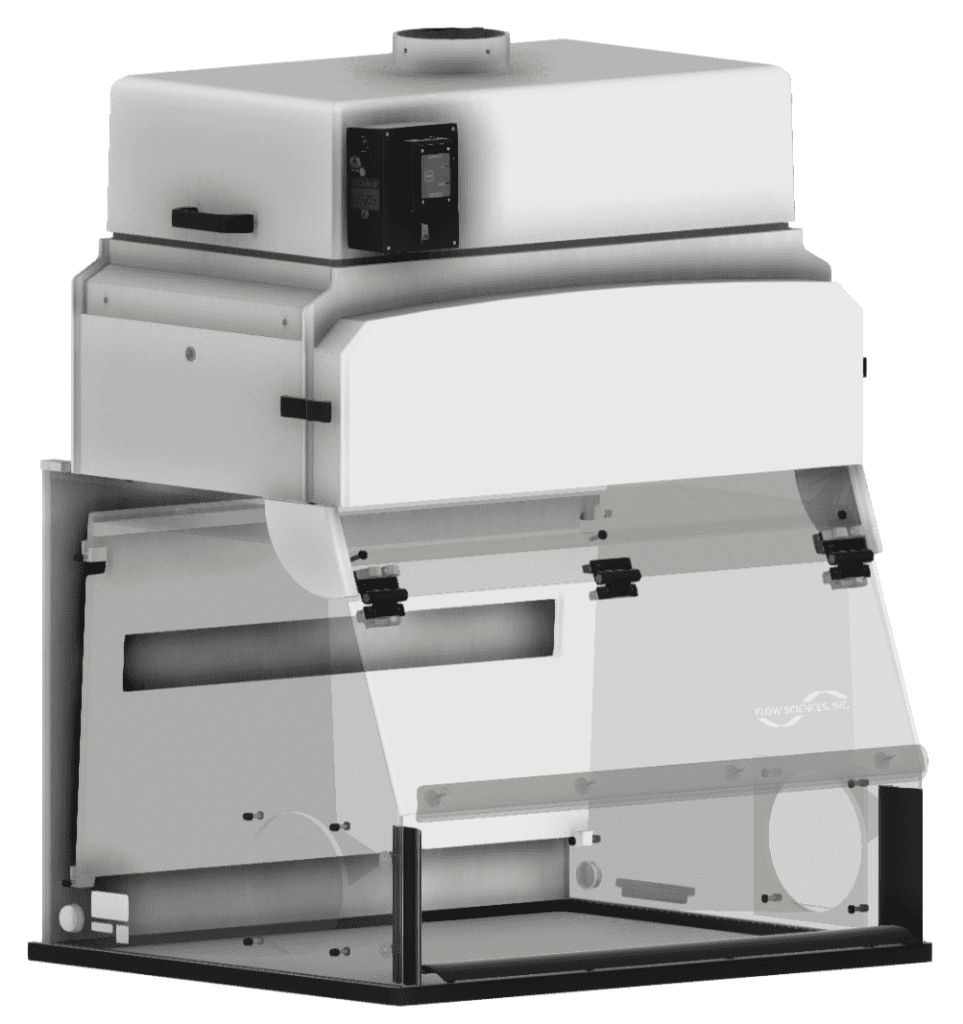

DUAL-HEPA

TOP MOUNT

HAZARDOUS, NON-STERILE

Flow Sciences Contained Vented Enclosure with Bag-In / Bag-Out Dual 4” HEPA filters and fan.

• RECIRCULATE into your lab to save money by requiring less make-up air and not venting out conditioned air

• FLEXIBILITY with placement in lab. Recirculate and move enclosure without moving house exhaust drops.

• Stable airflow and NO VIBRATION on the work surface