ABSTRACT:

Stability of your weighing balance is paramount when it comes to collecting reliable data for project. As the old adage goes, “Anything that can go wrong will go wrong.”. Depending on the problem, taking obvious action for a seemingly obvious solution may not result in success.

The purpose of this paper is to inspire thought and dialogue regarding those “not so obvious” sources of balance stability issues. Below, you may find 10 prompt questions that will hopefully guide one in resolving those pesky head-scratchers:

1 – Is the work surface causing instability?

Placing leveling pads on the bottom of the legs of the workbench or table is a useful tactic to prevent inaccurate readings caused by wear-and-tear of the leg undersides.

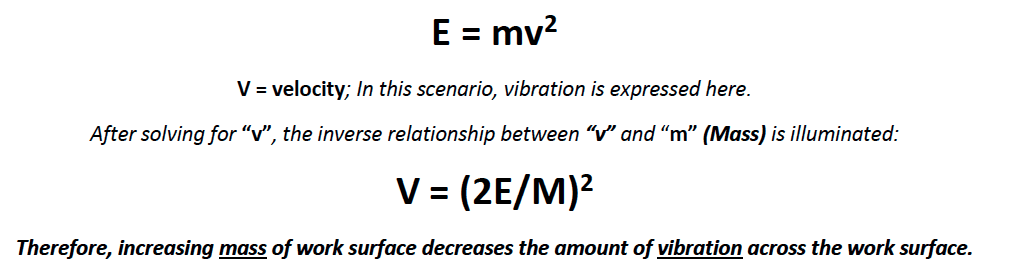

Additionally, the mass of the work surface affects the severity of data noise caused by vibration. The relationship between mass and vibration (kinetic vibration energy) can be illustrated by applying Newton’s law of Kinetic energy:

Although a rare case and dependent on region, buildings sinking into the soil has the potential of being a problem. In regions near fault lines, there may be a slight change in elevation that could impact measurements at high sensitivities.

2 – How is data reproducibility affected when weighing operations are conducted inside an enclosure or fume hood?

Vibration interference caused by an enclosure fan is commonly-cited disturbance in the lab. What are some ways where the vibration can be reduced?

3 – What can cause vibrational interference?

Other than an enclosure fan, other equipment in the vicinity of your balance may be vibrating through the materials between them. Some pertinent examples are floor-mount grinders, tablet grinders, etc.

At higher sensitivities, foot traffic near the operation could lead to error. Vibration may travel from the floor and through to the legs of the workbench or other work surface. The end result could be loss of powder or error due to disturbance of the powder.

4 – How can the construction of the enclosure affect weight measurements?

Depending on the construction of your work surface, you may experience measurement error caused by electrostatic interference. As the diameter of testing material continues to shrink, particulate is becoming increasingly susceptible to the electrical charge of the surrounding environment.

Static dissipation is a critical consideration during the design of our products. Chlorosulfonated polyethylene (CSM) gloves are a component of our EHA (Hybrid Isolator Series) and Butyl gloves are a component of our END (Nitrogenema) Series. The base of the Hybrid Isolator Series is phenolic and the superstructure of the Nitrogenema Series is composed of static dissipative acrylic.

5 – What are factors that contribute to static interference? What are some control methods you could employ for abatement?

In the powder world, static electricity is more than just that annoying winter zap when you touch a doorknob. In the lab, employees’ clothing/personal protective equipment, laboratory furniture, and even the construction of the Heating, Ventilation, and Air Conditioning (HVAC) system servicing are some factors that could lead to product loss and erroneous measurements.

We recommend that you keep the balance where it is upon sitting it on the work surface or inside the enclosure. Moving the base across a surface, especially if the surface is made of material different than the base, may cause enough static charge to interfere with your measurements.

6 – How does organization of equipment inside the enclosure affect results?

Depending on the type of enclosure and equipment you’re using, your balance may shift over time. Multiple uses of the balance over a long period of time may cause the balance to shift towards the enclosure face. In turn, air moving over the airfoil can blow some of the powder off the balance. At higher sensitivities, it could even bias measurements due to the force onto the weigh boat and/or the pan. Flow Sciences recommends that the balance be placed at least 6 inches behind the base airfoil.

7 – How can the balance be oriented to achieve optimal data reproducibility?

Organization of your equipment inside the enclosure can incur interference due to air currents moving around equipment. Just like a scale that is too close to the enclosure face, interference may be caused by air currents moving around other equipment. Vibration from other equipment, such as capsule machines, can cause vibrational interference. Flow Sciences recommends organizing your equipment such that these interferences do not occur. Don’t forget to consider putting your equipment at an angle; it just may work in a pinch.

8 – What are the moisture-retaining properties of your powder?

If you’re shrugging your shoulders over lousy regression lines, it may not be you or your equipment. It could be the powder itself absorbing moisture from the atmosphere. At higher sensitivities, hygroscopicity has a tendency to rear its ugly head. What could you do to prevent this kind of interference?

Additionally, product purity is negatively impacted by its own hygroscopic properties. Flow Sciences recommends performing your operation in a closed, controlled environment purged of oxygen. For example, a contained environment enclosure with automated nitrogen purging cycles, such as Flow Sciences, Inc.’s Nitrogenema Glove Box.

9 – Have you checked your certification results and calibration certificates recently?

Sometimes, the solution to the problem is not where we have our “mental crosshairs” set. Lab managers place much trust on their lab equipment. But, have you checked your certification results recently? Have any calibration certificates expired?

10 – Is there anything going on outside the lab building?

Do you live near an airport? Just like dropping an object onto the exterior of the enclosure negatively affects balance measurements, that humming of the plane is a vibration itself. Is that annoying jackhammer actually sabotaging your weighing operation?