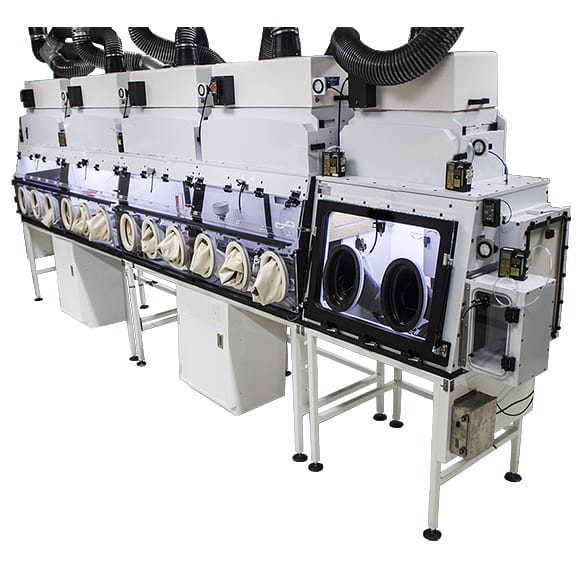

DESCRIPTION

API Process Development System designed to provide personnel and product protection while working with powder and liquid substances. Designed to house a Mettler Toledo Easy Max 102, Vacuum Oven, and IKA LR 1000. System features include acrylic superstructure for Isolators, polypropylene superstructure for Glovebox Workstation with clear opening pass throughs on left and right side, inlet HEPA filtration, black phenolic base, acrylic viewing panels, hinged door style, BIBO filtration with dual HEPA, top mount fan, vent kit, 5x thimble connections, acrylic left side pass through, polypropylene right side pass through, removable draft shields with 12 x 8” oval glove ports on isolators, 2x 10” glove ports on glovebox, minihelic gauges, LED internal lighting, 6” solid waste port with continuous liner, 3x tables, 2x vacuum pump cabinets with power switches, and main electrical box for fans and on/off switch for lighting. LED lighting and Acrylic viewing panels maximize lighting across the workspace.

Enclosure Dimensions:

252” Exterior Width

30” Exterior Depth

101” Exterior Height

PERFORMANCE TESTING

Performance is paramount in the safety industry. Through consistent design quality and expert manufacturing, Flow Sciences’ units perform. With surrogate powder testing both in our facility as factory acceptance testing (FAT) and at the customer facility as site acceptance testing (SAT), we consistently exceed our customers’ containment targets and goal expectations.

FLOW SCIENCES CONTAINS. FLOW SCIENCES PERFORMS.

Containment Target : 1,000 ng/m³

Surrogate Powder Testing Result : 0.51 ng/m³

Equipment : Balance, Filter, Vacuum Oven

Operation : Weighing, Filtering

Test : Lactose – 3 x 500g