Allan Goodman, Ph.D., Flow Sciences

Robert Haugen, Ph.D., Flow Sciences

Abstract:

Flow Sciences has more than three decades of experience in designing, manufacturing and testing powder containment devices, predominantly for the pharmaceutical industry. These enclosures have evolved from small balance containment devices connected to remote blowers, to a variety of custom and standard products.

This increased product diversity has been achieved while maintaining the necessary features required for superior containment and airflow conditions conducive for enabling highly sensitive operations such as microbalance weighing and mixing and reacting chemicals.

No product reflects this sophistication more elegantly than the chemical fume hood. Originally designed around 350 years ago to contain accidents and prevent bad odors in the laboratory, the fume hood has become a device that can routinely produce control levels of vapors down to the part-per-billion level. This is particularly important because many researchers may be unaware of the toxicity or even the identity of chemicals routinely produced in experimental chemical reactions.1

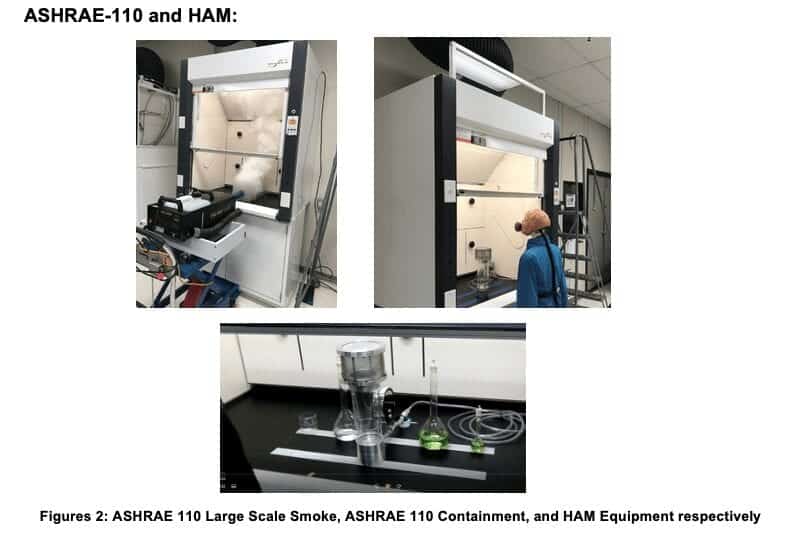

In the United States, the primary containment measurement methodology for fume hoods since the late 1970’s has been ASHRAE 110. The latest version of this test, ANSI / ASHRAE 110-2016, uses an SF6(g) diffuser and mannequin with air sampler to determine a tracer gas presence in the breathing zone of a mannequin.2 A limitation of the ASHRAE test is that it is mostly static in nature and, other than the Sash Movement Effect (SME) component, involves no human interaction. In spite of these limitations, most manufacturers of fume hoods sincerely believe that containment of SF6 gas under the ASHRAE test conditions is a reasonable predictor for particulates as well as vapor containment.

This argument remains unconvincing for many of our customers. Indeed, many industrial hygiene organizations and personnel have not recommended the use of fume hoods for powder manipulation operations of any kind. It is therefore necessary to find new tests which quantify performance and limitations for fume hoods in the context of finely divided powders.

We have therefore chosen here to meld existing techniques centered around ASHRAE 110 with widely-accepted particulate containment measurement techniques4. This combined regimen was then directly applied to a 4’ fume hood so results of all tests could be compared with each other. If results were found to be consistent, a new combined test using all three phases of matter could be established.

The test results obtained here allow us to make some rather positive preliminary conclusions in this regard.

Introduction:

Flow Sciences offers a wide range of enclosure types, including the ‘Saf – T Flow’ series of fume hoods. The FAF483055VAA fume hood has a vertical sliding sash enclosure, and airflow through the unit is achieved using a duct system to an exhaust fan with air leaving the building. (Figure 1)

Testing of the unit was broken out into the following components:

- ASHRAE-110

- Face Velocity

- Smoke Visualization

- Tracer Gas

- HAM

- Surrogate Powder / Solvent

The ASHRAE-110, SF6HAM and surrogate material tests were performed at the Flow Sciences facility in Leland, NC.

Other than the SME, the ASHRAE-110 test is static in nature, while the other components are dynamic and require human interaction in and around the face opening of the fume hood. The various tests use different materials, allowing the tests to be used independently, to validate containment performance of the fume hood, or compared to one another to determine each test method as a predictor of the level of containment offered by the equipment.

Testing:

Materials used for the testing of the fume hood are either used in standard testing or are acceptable surrogates. Sulfur hexafluoride is the tracer gas used for the ASHRAE testing and is released at a constant rate determined by the ASHRAE-110 standard. Lactose is an acceptable surrogate powder as defined by the ISPE good practice guide – Assessing the Particulate Containment Performance of Pharmaceutical Equipment. Methylene chloride was chosen as the solvent as it is fairly volatile at ambient temperature and does not have appreciable solubility capacity for lactose. For both of the surrogate materials, sufficient quantities were utilized to provide a robust benchmark challenge to the containment capability of the fume hood.

| Test Material | Appearance | Particle Size | Density (g/cm3) | Quantity Used |

| Sulfur hexafluoride | Colorless Gas | ~ 3.12Å diameter | 0.0062 | 4L / min |

| Methylene Chloride (DCM) | Colorless liquid or gas | ~ 2.94Å diameter | 1.33 (l), 0.0035 (g) | 3 x 250 mL |

| Lactose Monohydrate | White, crystalline powder | <250 µm (≥99%) | 1.54 | 3 x 100g |

| For comparison, air has a density of approximately 0.0012 g/cm3 | ||||

Table 1. Summary of test material attributes.

The initial factory acceptance test followed the standard ASHRAE110 and ANSI/AIHA Z9.5 testing protocols using Sulfur Hexafluoride(SF6)as the tracer gas. The following tests were performed:

1)an average airflow velocity at the face opening

2)small and large volume smoke tests

3) a tracer gas test.

The ANSI/AIHA Z9.5 standard testing for the tracer gas was followed, using the generally accepted 50 ppb threshold for factory acceptance. The tracer gas used in the experiments was 99.95% pure sulfur hexafluoride, set at a flow rate of 4.0LPM. The tracer gas ejector system is equivalent to that of the ASHRAE-110 standard ejector system. Table 2 shows an overview of the test results.

| Test | FAF483655VAA | |

| Average Airflow Velocity (fpm) | 80.75 ± 4.95 | |

| Low Volume Smoke Rating | Good | |

| Large Volume Clearance Time (s) | 25 | |

| Average TracerGas Reading (ppb) | Static | 0.00 |

| SME | 0.00 | |

| HAM | 2.80 | |

Table2. Summary of general performance testing

It is possible to convert ppb of sulfur hexafluoride directly to units more commonly used in the industrial hygiene field through the following conversion factor:

1ppb = 5.98 µg/m3

Therefore, it is possible to calculate the release rate (inside) and escape concentrations (outside) of the sulfur hexafluoride during testing. Table 3 shows the release rate concentration and the Short Term Exposure (STE) and Time Weighted Average (TWA) levels of the tracer gas during HAM testing.

| ppb | µg/m3 | |

| Release rate concentration | 364,161 | 2.18e6 |

| Escape STEL | 2.80 | 16.74 |

| Escape TWA | 0.015 | 0.087 |

| Numbers are generated using the following values – CFM of unit tested @80.75 LFPM = 387.90; STE during 2.5 minutes sampling time; TWA based on STE and 8-hour work day. | ||

Table3. Summary of ASHRAE testing converted to common OEL values.

Surrogate Testing:

All sampling was performed in accordance with the following: best Industrial Hygiene practices; the guidelines published in Section II, Sampling, Measurement, Methods, and Instruments, of the Federal Occupational Safety and Health Administration (OSHA) Technical Manual; and the ISPE APCPPE Guideline.

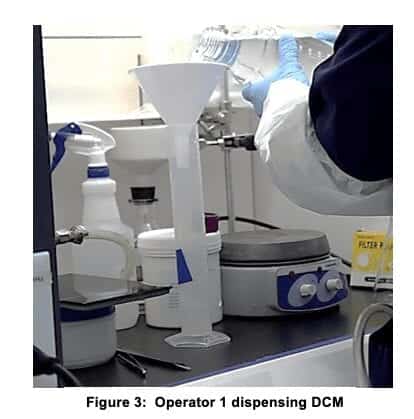

All samples were collected using filters and portable pumps. Some pumps were stationary both inside and outside the containment area, others were mounted on the experimental subjects as in figure 4 below. “Loaded” filters were then analyzed using validated analytical methods by a contract analytical laboratory accredited by the American Industrial Hygiene Association (AIHA).

In this study, lactose, an industry accepted surrogate, and methylene chloride (DCM) were utilized to determine the expected containment that a fume hood of this type would provide during manipulation of similar compounds during normal work practices. These operations included weighing, dissolution and filtering.

A detailed description of the procedural steps used in this test is available from the manufacturer but is considered beyond the scope of this paper. Suffice it to say, tared weighing, dispensing, vacuum filtration, data recording, and cleanup were the key steps. Table 4 shows a summary of the quantities of surrogate materials manipulated, the concentration of powder generated inside the fume hood and the level of material that ‘escaped’ from the fume hood during operations. As can be seen, for both of the surrogate materials utilized, no filters showed measurable quantities escaping.

| Operator | Surrogate | Amount Handled by Operator | Amount Collected on Outside Filters (escape) (µg) |

| 1 | Lactose | 100 g | <0.002 |

| DCM | 250 mL | <10 | |

| 2 | Lactose | 100 g | <0.002 |

| DCM | 250 mL | <10 | |

| 3 | Lactose | 100 g | <0.002 |

| DCM | 250 mL | <10 |

Table 4. Summary oftotal surrogate collected on filters outside fume hood.

During testing, a single filter was located inside the enclosure to measure the airborne concentration of lactose. Since only a single filter was used, the concentration for each operator was assigned to be the same. For DCM, volumes were measured at the start and end of the process for each operator. The difference in volume was used as a means to determine a worst case concentration of vapor (assuming total evaporation).5

Table 5 shows a summary of ‘Short Term Exposure’ (STE) and ‘Time Weighted Average’ (TWA) levels for each operator with both surrogates, both inside and outside of the fume hood. These values are useful in determining the suitability of control devices as various ‘Operator Exposure Bands’ (OEBs) exist and are often determined by the end user. (N.B. The TWA is based on the concentration determined for the STEL and an 8-hour work day).

| Operator | Powder | Concentration Inside (STE) | Max Outside (STE) (µg/m3) | Concentration Inside (TWA) | Max Outside (TWA) (µg/m3) | ||

| 1 | Lactose | 5.64 (µg/m3) | ND | 0.38 (µg/m3) | ND | ||

| DCM | 61.90 ppm | ND | 4.12 ppm | ND | |||

| 2 | Lactose | 5.64(µg/m3) | ND | 0.31 (µg/m3) | ND | ||

| DCM | 55.29 ppm | ND | 3.00 ppm | ND | |||

| 3 | Lactose | 5.64 (µg/m3) | ND | 0.33 (µg/m3) | ND | ||

| DCM | 50.20 ppm | ND | 2.93 ppm | ND | |||

| ND – Levels were below reporting limit for analysis (2 ng for lactose; 10 µg for DCM) | |||||||

Table 5.Summary ofsurrogate concentrations inside and outside fume hood.

Table 6 shows a summary of the total number of samples collected and exposures to surrogate materials for all operators. Of the twenty-seven samples taken for each surrogate material for all operations, no samples showed detectable levels outside of the fume hood.

| Powder Tested | Total Number of Samples | Breathing Zone Samples | Area Samples | |||

| Total Number | Number With Detectable Quantities | Total Number | Number With Detectable Quantities | |||

| Lactose | 23 | 6 | 0 | 12 | 0 | |

| DCM | 4 | 3 | 0 | 1 | 0 | |

Table 6. Summary of operator.

Discussion:

From all of the data presented, it can be seen that the Flow Sciences Saf-T fume hood series, when used with good laboratory practices offers exceptional containment of potentially harmful substances. In static testing, the fume hood contained tracer gas to an average level of 0.00 ppb, well below the ANSI/AIHA Z9.5 standard threshhold for factory acceptance testing.

In the dynamic version of the tracer gas testing, or HAM testing, again the unit performed very well, with escape of the tracer gas at an average of 2.80 ppb. This suggests two things:

- That the fume hood provides exceptional containment even under situations more accurate of the desired use;

- That the static and dynamic tracer gas tests of Flow Sciences’ fume hoods are indicative of the level of containment provided.

During the surrogate testing, a more aggressive challenge was performed using two materials designed to mimic ‘real world’ operations. With both the ‘powder’ and ‘vapor’ surrogate materials, the fume hood offered superb containment. No filters from subjects or the test room showed measurable amounts of surrogates outside the fume hood.

Conclusions:

An extensive evaluation of the containment capability of an FAF483655VAA from the Saf-T Flow series of fume hoods offered by Flow Sciences, Inc. was performed using both static and dynamic testing conditions. In each of the tests performed, the level of material ‘escaping’ from the fume hood was significantly lower than concentrations generated inside. This is particularly important when the vastly different physical characteristics of the test materials is considered. Additionally, the static versus dynamic testing using the tracer gas showed excellent correlation, suggesting that either test is predictive of the containment capability of the fume hood. Furthermore, the containment shown during the very aggressive surrogate powder testing show that this style of fume hood is capable of offering excellent protection to personnel during tasks of the nature described.

Overall, the Flow Sciences fume hood, when used in conjunction with good lab practices, is capable of providing workers with the protection they need for applications using solids, liquids and gases.6

References:

- https://www.cdc.gov/niosh/docs/2012-147/pdfs/2012-147.pdf

- https://webstore.ansi.org/standards/ashrae/ansiashraestandard1102016

- http://ateam.lbl.gov/hightech/fumehood/doc/LBID-2561-HAM_SidebySide.pdf

- https://ispe.org/publications/guidance-documents/assessing-particulate-containment-performance

- The concentration of DCM was calculated based on the total volume loss of the liquid during each operator’s process and is assumed to be constant throughout the whole process.The total loss was converted to an average loss per minute based on duration of task. Using Ideal gas volumes (22.4L/mol) a vapor volume per minute was calculated. This was then converted to a ppm concentration based on the volume of air flowing through the fume hood.

- A full report containing all of the information presented here including the surrogate test protocol can be obtained by contacting Flow Sciences, Inc. at 1-800-849-3429.