Process

Effective against chemical vapors generated during processes including reflux, distillation, flash chromatography, evaporation, etc.

Containment

Unique design includes a bypass system using air entrapped by the hood to actively engage, contain, and exhaust fumes from the containment area.

Design

Similar overall design structure used in standard sizes to simplify lab planning, layout, and HVAC coordination.

Fume Hood Series

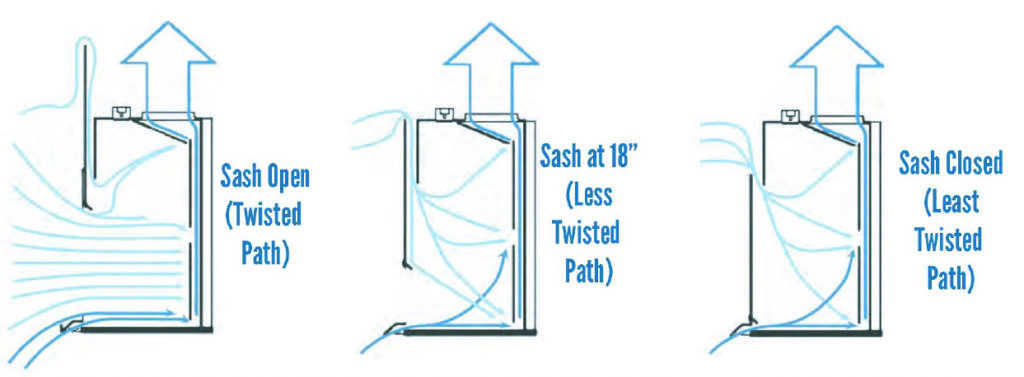

Overlapping Sash Bypass (OSB)

The overlapping sash bypass provides better containment and never needs to be removed or replaced if Variable Air Volume conservation systems are retrofitted into an existing SAF T Flow installation. In all exhaust applications, bypass air does productive work clearing fumes from behind the sash and means all exhausted air does containment work at all times.

We have tested our OSB from 100 FPM full open sash down to 60 FPM at 18″ sash opening with ASHRAE 110 containment equipment and cannot tell any difference in containment performance at any selected face velocity or opening with this range. Breathing zone containment from 0.005ppm down to undetectable.

Slide-out Top System

The slide-out feature allows complete top replacement without lifting the fume hood superstructure and disconnecting plumbing or ductwork.

STABILIZING BAFFLE CONTROL SYSTEM

Slots oriented in both X and Y axis promote even airflow back into the hood interior, from the top to the bottom of the sash opening. The rear baffle is removable for easy cleaning.

QUICK-SET SCAFFOLDING SYSTEM

Detachment knobs make for quick scaffolding setup and easy rear baffle removal for cleaning.

CLEAR CORD FLIP-UP AIRFOIL

Used for safe cord routing and air flow direction.

Steel SUPERSTRUCTURE AND CHAIN DRIVE

14 – 18 gauge framing system and #35 steel chain drive will run 50,000 cycles without breaking.

Custom Hoods

Flow Sciences has a team of engineers to design and manufacture a custom containment solution for your specific application

After production, FSI tests these enclosures in an on-site laboratory, and can also arrange 3rd party testing for Factory Acceptance Testing.

STANDARD BASE CABINETS

- Epoxy-painted steel construction

- Single intermediate shelf supplied

CORROSIVES CABINETS

- Epoxy-painted steel construction

- Interior lined with 3mm FRP panel

- Single intermediate shelf supplied

SOLVENT CABINETS

- Single intermediate shelf supplied

- Double Steel Wall Construction

- All flammable cabinets are built according to the construction standards expressed in NFPA30:Section 9.5.2(2)

Question or need a quote?

Contact us using our online form, live chat, or call 1-800-849-3429. We're here to help you find the solution you need.

Contact Our Experts

SEARCH CONTAINMENT BY APPLICATION

Build Options

| Product Type | Style | Liner Material | Ext. Width | Ext. Depth | Ext. Height | Sash Type | Work Surface | Voltage/ Alarm |

|---|---|---|---|---|---|---|---|---|

| F – Enclosure | A – Overlapping Sash Bypass | F – FRP | 48" | 30" | 55" | V – Vertical | A – Epoxy, No Cup Sink | A – 110-120v 50-60 Hz/ No Velocity Alarm |

| P – Poly | 60" | 95" (Floor Mount) | C – Combination | B – Epoxy, Left Front Cup Sink | B – 220-2400v 50-60 Hz/ No Velocity Alarm | |||

| S – 304 Stainless Steel | 72”" | C – Epoxy, Left Rear Cup Sink |

C–Un-Wired/ No Electrical Components (Cutouts Provided) |

|||||

| X – 316 Stainless Steel | D – Epoxy, Right Front Cup Sink |

D – 110-120v 50-60 Hz/ Face Velocity Alarm |

||||||

| E – Epoxy, Right Rear Cup Sink |

E – 220-240v 50-60 Hz/ Face Velocity Alarm |

|||||||

| F – No Work Surface |

| Add-Ons | ||

|---|---|---|

| Berkshire Cleaning Kit | Contact Flow Sciences for kit description |

|